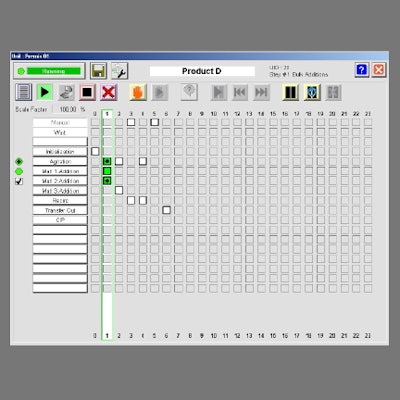

This allows users to configure sequences directly in the controller through the human-machine interface using a standard user interface. For system integrators, this feature eliminates the need for

engineering-intensive custom code, while OEMs can design a common

process control solution for end customers requiring local sequencing

that can easily integrate into a larger plant-wide solution. Designed

for stand-alone units like mixers, blenders and reactors that require

flexibility in the sequence (procedures) of the process and the

formulas (setpoints) for the recipe. It is also well suited for common

continuous sequencing applications like process startup/shutdown, grade

changes and cleaning skid control.

Companies in this press-release