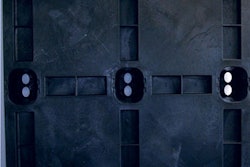

![[Caption for Milk_2] A 360 (degree symbol) Milk Pack effectively fits into any retail shelf/bin/case environment, regardless of](https://img.packworld.com/files/base/pmmi/all/image/2011/09/pw_10311_si_milk2.png?auto=format%2Ccompress&q=70&w=400)

We all realize the competitive shelf set in virtually every product category in every industry is becoming more crowded. As the world’s tastes continue to grow, massive product proliferation keeps in step. The effect this trend has on available shelf space is fast becoming another vitally important factor for marketers to consider.

Instead of merely trying to “pop” on-shelf graphically, any new package needs to be able to slice between competing products and innovatively fit in. When any new package finds its way onto the shelf, the necessity is the same as it’s always been; garner the attention of the passing shopper and entice interaction. However, now we must contend with a new reality: Available shelf space for new packages is shrinking.

The proliferation of products has been supported in part by the sharp increase in store construction. As more supermarkets, mass merchants, convenience stores, home centers, and club stores get built, they try to provide more shelf space for the dizzying array of new products. However, there is no standardization or modularization of horizontal shelves, vertical hanging surfaces, refrigerated and frozen cases, racks, and post-and-beam palette frames to automatically enable a new package to fit. As a matter of fact, the issues are compounded when you realize that many categories have matured over decades and shelves have evolved to become permanently affixed for a very specific package size. Any way you cut it, there isn’t any extra free space available.

An interesting paradigm has been perpetuated that seemingly obligates us to create any new package design with a definitive front facing, two sides, a top and bottom, and a back. We have become robotic in our approach to make any new package structure have an applied label and face it a certain way—our way. We have been trained to think that whether it’s a consumer-electronics package or a bottle of shampoo, we should look at it front-on in the store, and the more bottles of shampoo that are together, the better it is.

The dilemma

So there is very little real estate available for the plethora of new and extended branded consumer packaged goods. In a sense it is an ever-shrinking ratio. The physical space that packages are placed upon, hung from, or placed into isn’t inherently flexible to accommodate change. And, there are many preconceived and unchallenged notions of what the package structure should do on shelf, which by default drives non-innovation.

Can anything be done that won’t perpetuate physical parity and a de-emphasis of personality for your brand? The true innovative answer should be, “There’s a lot that can be done, and we just need to look at the issue from a different perspective to optimize the 3-D space available.”

The dilemma of shrinking shelf space can be highlighted and validated by an unlikely source—the stockperson at the supermarket. Consider the milk carton. It has a main front panel and it’s supposed to sit densely like soldiers in a row on a shelf next to other milk cartons. Now, it’s nearing the end of the week and there undoubtedly will be a rush of parents buying milk for the weekend and the beginning of their kids’ school week. The retailer knows this and needs to order a large shipment. The shipment comes into the store and needs to be put on shelf.

Work-around solution

Yikes, where did all the space go? Instead of “regular milk,” the typical cooler in today’s supermarket contains these varieties: 1%, 2%, skim, fortified, flavored, soy, non-dairy, lactose-intolerant, goat’s milk, and organic. With no space, perhaps it won’t be ordered in the first place, or one of your own SKUs is cannibalized to make room for it. Or one of your SKUs is removed in order to make room for a competitor’s new product. If the retailer selects a new item to stock, it needs to be placed in the cooler, where it needs to fit on the shelf.

What can you do with your package structure to make it work in the latter scenario?

Here is what a stockperson might do. Gary, a sales associate at Stop & Shop, has a dilemma and needs to think fast. A new large shipment of regular milk cartons has arrived at his store, and he needs to display it. The problem is there isn’t any room left.

Gary rationalizes that all the carton shapes are square, with a triangular gable top. In the lower bay of the cooler, Gary turns some cartons upside-down and places them on top of upright cartons. They fit perfectly. On higher shelves, he lays the cartons down and rotates them 45 degrees. Again, they fit perfectly. Gary also discovers he can stack the cartons another layer higher. In the process, he has effectively worked around the problem of reduced shelf space by utilizing available 3-D shelf cubic volume and exploiting the package shapes.

In this example, the milk carton has become a package structure gold standard of a flexible, multi-positionable package structure. The only problem is the marketing and sales folks at the milk company are very upset with the retailer for positioning their package upside-down in the cooler.

Based upon Gary’s solution to his space problem in the cooler, we are shown other potential solutions by observing his intuitive work-around to the dilemma.

Gary has solved the immediate problem and has also given us insight into uncovering the fundamental flaw of most packages as they relate to shrinking shelf space and the necessity to fit-in. Most packages are meant to be positioned in only one orientation, their labels are meant to be read only one way, the bottom is utilitarian and meant to be merely rested upon, the top is sacred and should always face upward, and the sides are meant to only touch the sides of the packages next to it. Yet, Gary figured out that the shape of a package structure should be adaptable and highly flexible in its orientations. Brilliant! And if a package structure is designed from the ground up in this fashion, it could do even more.

The opposite approach

Why do all package structures have to be herded onto a crowded shelf in the first place? Many branded consumer packaged goods are not commodity-based. The experience and delight of using the package is a far more apt method for articulating a brand’s value and distinctiveness to the consumer if it is presented in a more contextual or premium way.

Let’s think of the supermarket again, and this time we are shopping for dry pasta at Purity Supreme. We come upon 12 linear feet of rectilinear boxes of different colors, windows, pasta numbers, and names. The shopper thinks, “Was I told to get that specific brand of Fusill, or was it Vermicelli? What did that carton shape look like? I can’t remember it by name, but I remember sort of what it looked like the last time my wife made it.”

It looks as if we’re leaving with the wrong variety of pasta. There is nothing in the packages’ shape to provide any sense of ownable branding or a clue to the product form, unless the cartons have a window to provide a view of the product.

If we went to Whole Foods, we would have come across “areas” of smaller shelves that cluster products that are used together. In our case, dry pasta and sauce. This retailer even uses innovative displays to clearly show how the pasta looks when cooked in a typical serving and setting. Seeing it as if it were being served in a restaurant is certainly far more experientially appealing and visually unique and memorable than gazing at hundreds of generic rectangular shapes and trying to decipher any distinction.

Be opportunistic and flexible

The only consistency between retail venues is inconsistency. Foremost, your branded consumer packaged goods need to get in the store and find a place on the shelf. The shape needs to be flexible enough to adapt to a multitude of configurations. Once inside the store, your product needs to exude a level of visual aesthetics or use a “language” that leverages the brand’s positioning and serves as an iconic element in the shopper’s mind, regardless of its “misplacement” on the shelf. No matter how it is displayed, it has to look like it was supposed to be stocked that way.

Another solution to shrinking shelf space might be to flaunt the product or usage occasion to infer the experience of using the product. Sometimes, you can have an impromptu-looking display, either placed on the shelf or in close proximity to the product, and show it off. The package can be the backdrop to this theatrical setting, thus heightening the visual value of its shape and potential functionality, and it can be associated more closely with the delight and pleasure of the experience.

Otherwise, you’re merely just another rectangular box on the shelf. How boring!

The conceptual packaging illustrations and captions that accompany this article are our effort to present some solutions to the dilemma of shrinking shelf space.