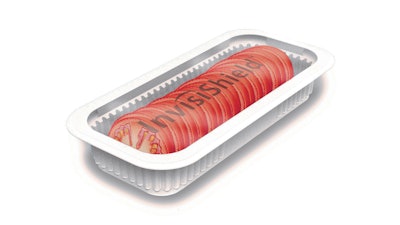

Food safety often keeps processors up late at night as they seek innovative ways to keep contaminants away from their products throughout the supply chain. Aptar Food + Beverage intends to ease some of that worry with InvisiShield, an anti-microbial packaging technology that protects fresh-cut produce from harmful pathogens without affecting the quality of the food.

Launched in March by Aptar Food + Beverage, a division of Crystal Lake, Ill.-based AptarGroup, which makes active packaging systems and equipment, InvisiShield is designed to help food manufacturers heighten their defense tactics against foodborne illnesses. “Even with good manufacturing practices in place, you still find recalls and outbreaks within fresh products. [Processors] don’t have a true kill step,” says Angela Morgan, Ph.D., director of business development at Aptar Food + Beverage. “So this is the first of its kind, a technology that actually works after the package is sealed when there’s no longer risk for cross-contamination. What makes this solution so different from all the other interventions that are on the market is it happens inside a sealed container that will no longer be cross-contaminated.”

Getting defensive

InvisiShield consists of an extruded 3-Phase Activ-Polymer technology, which is patented by Aptar CSP, a division of AptarGroup. Moisture from the food in the sealed packaging triggers a proprietary channeling agent that moves through the polymer and releases chlorine dioxide gas into the headspace at controlled doses over a 12- to 24-hour period. According to the company, third-party validation studies have proven that the chlorine dioxide gas in the packaging achieves a 1.5- to 3-log reduction for various foodborne bacterias, viruses, and fungi, including salmonella, E. coli, and listeria monocytogenes, without affecting the product’s color, flavor, aroma, and texture. InvisiShield has earned GRAS (Generally Recognized as Safe) designation from FDA.