At current production levels, the move will eliminate 150 tons of

paperboard from going into New Belgium packaging, while preventing 174

metric tons of carbon dioxide emissions each year. In addition, the

transition will save New Belgium an estimated $280,000 in the coming

year.

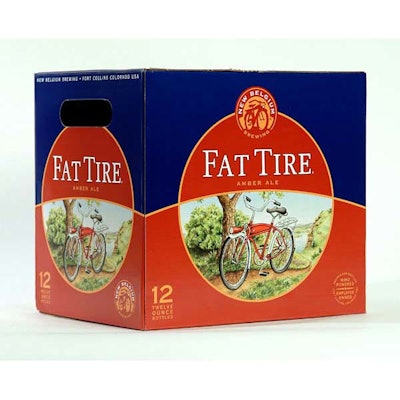

"We've designed a new 12-pack carton that will tighten the case to

prevent bottles from hitting each other during transit," says director

of operations Mark Fischer. "We ran the initial test of 2,500 cases

into our local market with no complaints or breakage issues."

Known as an industry leader in minimizing resource consumption, New

Belgium has long sought to reduce, reuse, and recycle throughout its

production process. Reducing consumption of paperboard has the added

benefit of cutting costs.

"We researched this decision thoroughly, and the vast benefits are hard

to ignore," adds New Belgium's sustainability director, Jenn Orgolini.

"We are continuously looking at new ways to improve our processes, and

this shift makes a lot of sense."

Consumers will start seeing the new 12-packs immediately for some New

Belgium beers, while the remainder of its existing Fat Tire inventory

will be used through February 2009. "Folly" packs, or mixed 12-packs,

will still use the partition due to the logistics of hand-packing.