If James Bond’s mission were to uncover areas on a bottling line that were causing damage to glass bottles, he might try the wireless glass-bottle inspection system used by member companies of the Swedish Brewers Assn.

The inspection system measures vibration and impact on glass bottles to identify handling abnormalities on bottling lines so that line personnel can take action to reduce glass bottle damage and breakage.

The customized system is supplied by Sensor Wireless. According to Sensor Wireless, the system was initially developed for use on Prince Edward Island, Canada, the supplier’s headquarters, where returnable glass bottles are used exclusively.

The system includes a cast-acrylic “Smart Bottle,” built to SBA’s specifications, that provides breweries and beverage makers in Sweden instant handling and performance characteristics from the perspective of a container on the bottling line. SBA member bottlers “borrow” the inspection system for use on their own lines.

Two sizes, 33 cL and 50 cL, are used to fit Sweden’s returnable glass bottle system (see sidebar, opposite page). One Smart Bottle is manufactured for both bottle sizes. The Smart Bottles are identical in size and shape to the clear and amber glass bottles that are conveyed through bottling lines at Swedish breweries, soft drink, water, and cider beverage plants. What differs is that the bright yellow Smart Bottles used by SBA member firms house built-in electronics, a radio-frequency transmitter, and single-axis accelerometers located at the shoulder and heel that measure vibrations and impact at any area on the bottle’s surface. These measurements help the Swedish brewers and beverage producers locate areas on the line that could cause bottle damage and breakage.

The vibrations detected by the system could emanate from an automated depalletizer; or as bottles move along the conveyor; during starting and stopping of the line; if they make contact with guiderails; as bottles contact other bottles at merge points; or at downstream packing equipment. Because they store sensitive electronic components, the Smart Bottles are not sent through rinsing, filling, or capping equipment.

Vibration and impact are measured by the amount of energy exerted on the bottle. These measurements are transmitted via radio frequency to the second key component of the system: a portable Palm® hand-held computer that delivers immediate feedback. The information can then be downloaded from the Palm to a personal computer equipped with specialized software to track bottle activity. The PC can display the data as an easy-to-interpret digital graph. The system costs just under $12ꯠ, according to Sensor Wireless.

Carlsberg drives Smart Bottle use

The Stockholm-based Swedish Brewers Assn. was made aware of the inspection system through its largest member, Carlsberg Breweries A/S. So far, Carlsberg and Spendrups are the only two SBA members to have used the Smart Bottle system.

“Our goal is to conduct initial monitoring of bottling lines at all 25 of our member companies this year, and then try to do follow-up visits every year,” explains Sven Romander, SBA’s technical manager. Future monitoring would ideally show reductions in glass bottle damage or breakage.

Romander has the responsibility of visiting its member company plants and evaulating lines to determine sources of bottle damage. “In the past, all I could do was look at the bottles and visually determine damage. Now damage can actually be measured.”

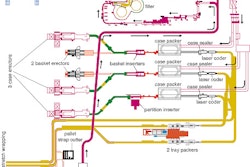

Line measurements usually require three people. One watches the Smart Bottle as it is conveyed through the line. A second person uses the Palm computer that receives signals from the Smart Bottle. That worker reports to a third person who has a drawing of the line. He transfers measurement data taken from the Smart Bottle at different points on the line onto the corresponding area on the line drawing.

The Smart Bottle measures the magnitude of impact or vibration on the bottle and assigns that impact with a numerical valuation, or magnitude. Romander describes the measurement in inches per second, not the speed or movement of the Smart Bottle, but the measurement of the vibration or impact on the Smart Bottle.

“We’ve set a limit of between 10 and 15 inches per second,” says Romander, which is based on information we developed with our glass bottle suppliers in Sweden and Estonia. At 25 inches per second, the bottles break.”

“With this system, we see exactly what’s happening to the bottle and the impacts it’s subjected to on the bottling lines,” asserts Romander. “On one of the lines, for example, we found that after automated depalletizing, bottles were conveyed at full speed and shortly thereafter brought to a complete stop. The impact of that action was almost causing the bottles to break, so the brewery made adjustments to slow down the conveyor in that area, and added plastic mechanical devices so that as bottles went by them, they were slowed down. The system helped provide an inexpensive solution.”

Another example of how the Smart Bottle system provided benefits was in an area where filled and crowned bottles were transferring from one conveyor to a multilane, multibottle conveyor. At this merge point, bottles “have a big impact,” says Romander. “We were able to use the measurements from the system and assign proper speeds to the conveyors for greater damage control.”

At soft drink producer Spendrups, Romander says, “we went through a line and found that they made a lot of stops on the line, particularly as the bottles went past an inspection machine that checked for foreign objects in the bottle just after a bottle washer. We used measurement data and found that making a simple change to synchronize the conveyor line with the speed of the bottles as they discharged from the inspection machine helped reduce damage.”

Developing a base line

“We don’t have any records to show specific improvements at plants yet because we just started with our two largest breweries last year,” says Romander. “These initial measurements will give us a base line to compare with in the future. So far, the breweries have responded very positively. They see we’re just beginning a process to make their operations better, and they want to [use] the system more.”

Romander says the Sensor Wireless system’s greatest potential asset will be to make sure a previous problem doesn’t reoccur. “We had a problem about five years ago where one of our members lost a lot of money even though their company was not responsible for bottle damage.”

In Sweden, where all 25 of these member firms end up filling the same undecorated bottles (glued-on paper labels provide product details and points of differentiation), it’s easy to see how vexing this problem could become—and how potentially litigious.

“We try to get 40 trips per bottle,” says Romander, which equates to about 10 years’ worth of use. “But we have bottles that date back to the fifties,” he insists. “And maybe with this system, instead of getting 40 trips, we’ll get 50!”

See sidebar to this article: SBA plays central role in Sweden's returnable glass bottle system