When Ocean Spray was about to introduce a new 1-gal jug with an unusual handle affixed to its side about 18 months ago, engineers at the Henderson, NV, plant discovered that it wouldn’t run well on the filling machine designated for the bottle.

“We discovered we had a problem with the radius of the discharge starwheel and the number of pockets on it,” reports Steve Daniels, who then served as technical resource at the plant. “We couldn’t make the existing starwheel deep enough to accommodate the bottle and handle without causing spillage.” Because of the handle’s side location, the starwheel had to be positioned low on the bottle, so it jostled the filled bottle.

At first it appeared the plant would need major modifications made to the filler. Not only would that cost an estimated $35ꯠ, but the plant’s production would incur at least a week’s worth of downtime while the filler was shipped back to the manufacturer to make the changes.

Even worse, Daniels says, the new package for Lakeville-Middleboro, MA-based Ocean Spray was scheduled for a rollout on the West Coast, so the plant had a production deadline to meet. “One of our engineers came up with an idea for a discharge starwheel with spring-loaded fingers that would handle the jug no matter where the handle happened to be when the bottle came out of the filler,” Daniels says. “We felt it could work to eliminate the spillage.”

Another plant worker recommended Morrison Timing Screw Co. (Glenwood, IL) because he had worked with them in the past. “He said that Morrison was particularly adept at listening to customers’ needs and providing exceptional service,” Daniels notes.

Two-day service

So the plant contacted Nick Wilson at Morrison, and later sent him a pencil sketch of the concept of the spring-loaded fingers on the starwheel. “We heard back immediately from Wilson,” says Daniels, “and the company said it would be here to install the new part in just two days!”

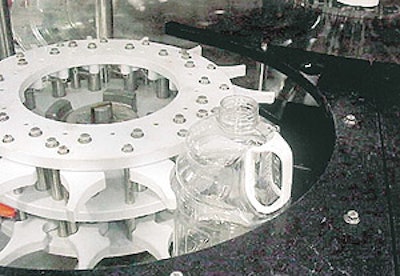

“A speedy response to Ocean Spray’s request was of the essence,” Wilson points out. “Working from that pencil sketch in lieu of engineering drawings, our plant manufactured a special Stars and Guides container transfer system consisting of the starwheel and guides for the filler. When we installed it at Henderson, we found that it needed one small change.”

While the Morrison engineers were at Ocean Spray, they faxed back to their plant the one change the system needed. The plant manufactured the part and sent it overnight to Ocean Spray’s plant. “When we walked in at 6 a.m. the next morning, the new part was in place on the machine and we were ready to run,” Daniels points out. “From that point on, it was successful.”

As a result, Daniels adds that the company saved the $35ꯠ for the filler rebuild, plus most of the downtime and lost production that having the filler modified would have caused.

Ocean Spray also got a bonus. Because of the way the spring-loaded fingers were designed, the plant can also use it for most of its 64-oz bottles. “So that eliminates our having to install a change part every time we switch bottle sizes,” Daniels says. “I was really impressed.

“The engineering ability, resourcefulness, and customer service they provided was incredible. And the Stars and Guides system works as well today as the day it was installed,” Daniels adds. “We’ve been so pleased that we’re using Morrison for changeover parts at our Kenosha, Wisconsin, and Sulphur Springs, Texas, plants now. And we have several more projects in mind for them, too.” —AO.