Made from cotton-seed hulls and mycelium, or mushroom “roots”, new protective packaging for Steelcase Inc.’s Currency line of ready-to-assemble office furniture has earned packaging supplier Ecovative (www.mushroompackaging.com) the Innovator of the Year award in the Non FDA-Regulated Products category of the 2011 Greener Package Awards. (In June, Ecovative was also named as a DuPont Award winner: see pack

world.com/package-31995.) Says awards judge Frank Perkowski, of Business Development Advisory, “This is truly an innovative packaging solution that has obvious environmental benefits relative to existing technologies.”

As Sam Harrington, environmental director and packaging engineer for Ecovative, recalls, Steelcase approached Ecovative in 2009 with the desire to replace the expanded polypropylene foam used as protective packaging for its products shipped globally. “They researched and sought out other packaging solutions,” he recalls, “but couldn’t find anything that would come close to the cushioning properties of the EPP and EPS [expanded polystyrene] parts they currently used—until they found Ecovative. They ultimately wanted the same or better protection, and far less environmental impact for about the same cost.”

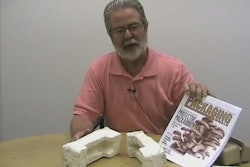

Ecovative’s EcoCradle is a low embodied-energy, compostable, protective packaging material that is literally grown into any custom shape. The company uses mycelium to bind together locally sourced agricultural byproducts, in a mold of any desired shape. Says the company’s Greener Package Awards entry form, “The materials we’ve developed over the last three years at Ecovative represent the first time humans have capitalized on the amazing structural properties of another kingdom of biology: fungi.”

EcoCradle packaging can be grown within five to seven days, in a dark, indoor environment, using one-tenth the energy used to manufacture traditional synthetic material. Currently Ecovative’s upstate New York pilot plant has the capacity to produce 10,000 packaging parts per month. The company is also in the process of building a much larger facility with 10-times the capacity, relates Harrington.

For Steelcase’s 300-lb ready-to-assemble furniture line, Ecovative “grew” corner blocks and flat slabs measuring 5 x 5 x 5 in. and 4 x 12 x 1 in., respectively. The parts were the culmination of a year-long development process in which Ecovative experimented with part molds, byproduct mixes, and other processes to ensure the packaging would meet Steelcase’s performance standards. Oat hulls were selected as a byproduct because they are local to Ecovative’s Green Island, NY, plant, thus minimizing transportation costs.

Being 100% biologic-based, EcoCradle also offers a nontoxic and convenient end-of-life option. The material is certified for home and industrial composting via ASTM D5210, 5338, and 6400 for both aerobic and anaerobic compostability, and can be “used as mulch or put in with yard waste,” explains Harrington.

Launch of the protective packaging was well received: “The Steelcase dealer network has been enthralled by EcoCradle,” says Harrington. “They often cite it as a shining example of Steelcase’s environmentally progressive designs and policies.”

Interestingly, the furniture maker is now taking a look at how else they might be able to leverage this unique, natural material, Harrington says. “Their designers have asked, ‘How can this be more than just furniture packaging? How can this be furniture?’” As a result, Ecovative is currently in discussions with Steelcase about applications in the furniture industry.