Berlin-based international meal-kit company HelloFresh has a large footprint: It currently operates in nine countries, delivered 23.9 million meals in the three-month period up to the end of 2016, and has more than 850,000 subscribers. That’s why, when it decides to make a change toward more sustainable practices, the impact can be significant.

This year, HelloFresh has launched an insulated container for its meal kits that is made from 100% recycled paperboard, is 100% recyclable, and is designed for ease of recycling. The company is the first in the meal kit market to use the northbox™ insulated container from Cascades to keep its food insulated for optimal freshness in transit and take the guesswork out of recycling for customers.

“At HelloFresh, we want to make the entire cooking experience more convenient from start to finish,” says Uwe Voss, COO of HelloFresh U.S. “By making it easier for customers to recycle with new packaging from Cascades, we’re confident it will encourage them to dispose of their boxes week after week in a sustainable way.”

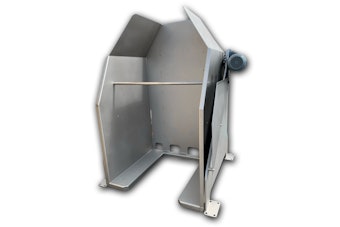

Before rolling out the new box to a large number of its customers in the U.S. in Q2-2017, HelloFresh was using “other insulated liners common in the meal kit industry,” explains Voss. The northbox is made from an outer corrugated box available in a number of sizes and insulation technology that consists of an FSC-certified paperboard structure and a reflective lining attached with water-based glue. The encapsulated metallized layer is 100% pulper-safe and allows for complete fiber recycling.

The insulator comes in three primary specifications, each of which corresponds to a certain temperature band—established through testing—from colder to warmer temperatures.

The insulator consists of two C-shaped paperboard liners designed to enhance the box’s stacking strength and speed the pick-and-pack process. The box and insulator are shipped flat, optimizing transport and storage as well as assembly. “Initial feedback from our distribution centers is positive,” says Voss. “Our production team likes the box because it is easy to assemble and pack. Even more importantly, our customers like it because it is easy to disassemble and dispose of.”

To advise customers of the fact that the box is 100% recyclable, HelloFresh includes a recycling symbol on the flap of the box and provides details on the recycling page of its website.

Voss says HelloFresh will be introducing a revised and more compact architecture for its box to reduce material waste and increase its shipping efficiency, “which further reduces our environmental footprint.” He adds, “We made sure to thoroughly test all opportunities that the added strength from the northbox interior insulation provides us before we made a final decision on revised box specifications. This will ensure we deliver the best and most sustainable product to our customers.”