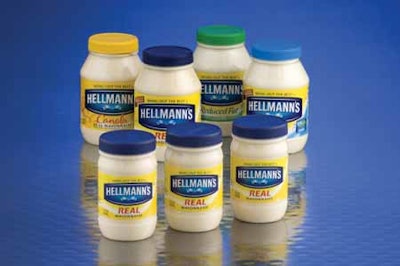

Unilever converted its 32-oz Hellmann’s jars to PET in 2005 and is now rolling out the conversion of its 15-oz jars.

Vinod Bansal, group manager, packaging technology, says the decision to convert the two different jar sizes was made at the same time, but he believes the two-stage launch eliminated the need for going through the same learning curve twice.

“We had already converted the lines from glass to plastic to run the 32-oz jars. Adding the 15-oz jars a few months later was virtually seamless,” Bansal notes.

Bansal explains that it’s more economical to convert to PET in larger jar sizes; the resin weight-per-unit volume decreases

as the jar size increases. However, Unilever determined the economics were right for the 15-oz container when it opted to use blow-and-trim technology from Amcor PET Packaging (www.amcor.com).

Blow-trim technology has existed for years, but Amcor’s two-step, higher-volume blow-trim process gave Unilever the economics it needed to convert the smaller jars to PET, Bansal says.

Both container sizes have the same finish, enabling further economies of scale in using the same closure—a 70 mm lined polypropylene lid from Berry Plastics (www.berryplastics.com)—on both jars.

Your Brand’s Survival May Depend On Smaller Packaging

As Wal-Mart ramps up its environmental sustainability initiative, the retailing giant is asking brand owners to evolve into smaller packaging with reusable/recyclable materials within two years, or risk losing precious shelf space in Wal-Mart stores.

And don’t be surprised if Wal-Mart’s move influences other retailers to fall in step.

On the one hand, that’s not necessarily a bad thing. Consumer product goods companies are turning to contract packagers to fill and pack their products while they focus solely on creating and marketing products. Surging energy and materials prices have increased the cost of many co-packing contracts by 5-10% or more over the past year. So lower costs that may accompany smaller packages would be welcomed.

On the other hand, Wal-Mart’s ambitious objective presents significant challenges for brand managers and marketers alike. Consider laundry detergent. Managers responsible for some of the nation’s top-selling and most trusted brands will be challenged to maintain the integrity of their products in the development of 2X and 3X concentrate formulas.

Marketers, in some cases, will face the formidable task of selling what amounts to new products to consumers without confusing them in aisles that are already saturated with myriad product choices.

My thought on this development is to gather your package-development and marketing teams now. Formulate a plan of attack that allows sufficient time for not just smaller packaging, but packaging that defines your product’s value. Brand owners that continue to treat packaging as an afterthought could be the losers in what appears to be the coming era of smaller packaging sizes.