Clabber Girl Corp., Terre Haute, IN, has been in business across three centuries. The venerable company’s latest packaging improvement will help introduce its products to new markets.

This modernized packaging matchmaker is in the form of a compact, U-shaped tub- or pail-filling and case-packing line currently used for products packed for fund-raising efforts. Soon the line will be used for club store accounts as well, according to Ed Wilkins, Clabber Girl’s executive director of plant operations.

In replacing a manual operation, Wilkins says the automated line boosts productivity and reduces changeover time in the plant. The case packer, from TAD Packaging Machinery, has also produced source reduction and materials savings.

“What prompted me to look at automatic case packing was the fact that we had several people on the production line and that production efficiency was low,” says Wilkins. “That caused restrictions for our ability to operate other production lines. We have reduced the number of employees for this function from a maximum of five to a maximum of two now. Our productivity has risen 40%.” Also, throughput nearly doubled. Those factors combined to produce a one-year payback, Wilkins says.

Wilkins points out that it is essentially a one-operator arrangement with the exception of the occasional ingredients packet that needs to be manually inserted into the pails for certain recipes.

Wilkins relied on distributor BelCorp for its expertise in machinery selection and service, though Clabber Girl installed the machinery itself. He also appreciates the vision and backing of Clabber Girl’s chief operating officer and president Gary Morris that made the line possible.

Starts with filling

Although the line has been in partial operation since 2003, a new filler from Burghof Engineering procured through BelCorp was installed in 2004 as a result of growing demand.

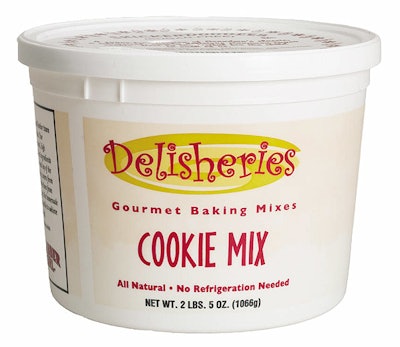

Nearly a dozen different dry powdered mixes are filled on the line, which runs over two shifts. The product net weights vary depending on the formulation. The day of our visit, the high-density polyethylene pails were filled with 2 lb 5 oz of cranberry cookie mix. Pails and HDPE lids are supplied by Berry Plastics. The pails are made of freezer-grade HDPE for durability, Wilkins points out. “Great product, company, and people,” says Wilkins. “Berry has always been very dependable.”

The Burghof machine is topped with an AMS auger filler that dispenses the powdered ingredients with 1% accuracy at a rate of around 42 pails/min, according to Wilkins. Pails are dispensed from a vertical supply magazine directly into a flight and carried one-up through the machine, heat-sealed with film, overcapped, and then discharged.

The pails are ink-jet coded as they round a tight curved conveyor on the way to the TAD case packer. Interestingly, there’s no checkweigher on the line at this point as this editor had expected. Because of the filler’s accuracy, a checkweigher is not needed, Wilkins says. He also credits BAH Engineering for the conveyoring that keeps product running smoothly between machines.

Case packing confidence

The case packer collates and transports the pails onto the wraparound corrugated in groups of six. The change from manual casing represents a significant cost savings for the company when they switched from taped RSC cases to the glued wraparound format. The blanks, preprinted in one color by Smurfit-Stone Container, are 29#ECT.

“That represents about a 30- to 50-percent cost reduction,” says Wilkins, “and the wraparound style is inherently stronger.” Storage space for blanks has been halved, he adds. Wilkins also believes the glued cases provide a more dust-proof seal than taped cases. This keeps the pails clean prior to unboxing by customers.

“We have had zero problems with the case packer,” says Wilkins. “We uncrated it, hooked it up, and it’s been running great ever since.”

Maintenance manager Dan Vice says the unit’s simple design means about 30% fewer parts than other case packers. For the two years in which it has been in operation, Vice says they’ve spent a grand total of $50 in maintenance for it.

“It’s an exceptional machine,” adds Wilkins.

The line has been packaging for the company’s fund-raising program since 2003, though that effort has been gaining steam over the ensuing months, according to Wilkins. He notes that the plant now operates the line over two shifts and could double capacity by upgrading to two-up filling. The case packer, he adds, can accept the increased output.

Clabber Girl is also planning a multipacked tray format for club store sales, Wilkins says, an addition that will be seamless for the case packer. “The case packer is versatile and will easily handle the tray—that’s a blessing,” he points out.

A similar installation will play a role in the company’s future. Wilkins says the company plans to add a second line with a TAD case packer in 2006 as the company’s offerings extend into food service.