Winemaker and president of Bonny Doon Vineyard Randall Grahm is no fan of the stuffiness that pervades most discussions of fine wines. So it was no surprise that his Santa Cruz winery became one of the first in California wineries to make a major commitment two years ago to the Stelvin® roll-on, pilfer-proof aluminum closure from Pechiney to replace synthetic cork.

In July 2002, Grahm announced that 80ꯠ cases of his best-selling wines, under the Ca’ del Solo label, would be converted to the easy-to-open alternative.

Two years later, Grahm and his winery haven’t looked back. This year, for example, the Ca’ del Solo label will be producing some 220ꯠ to 230ꯠ cases of bottles finished with the ROPP closure for Bonny Doon’s Big House Red and Big House White varieties, says John Locke, winery spokesman.

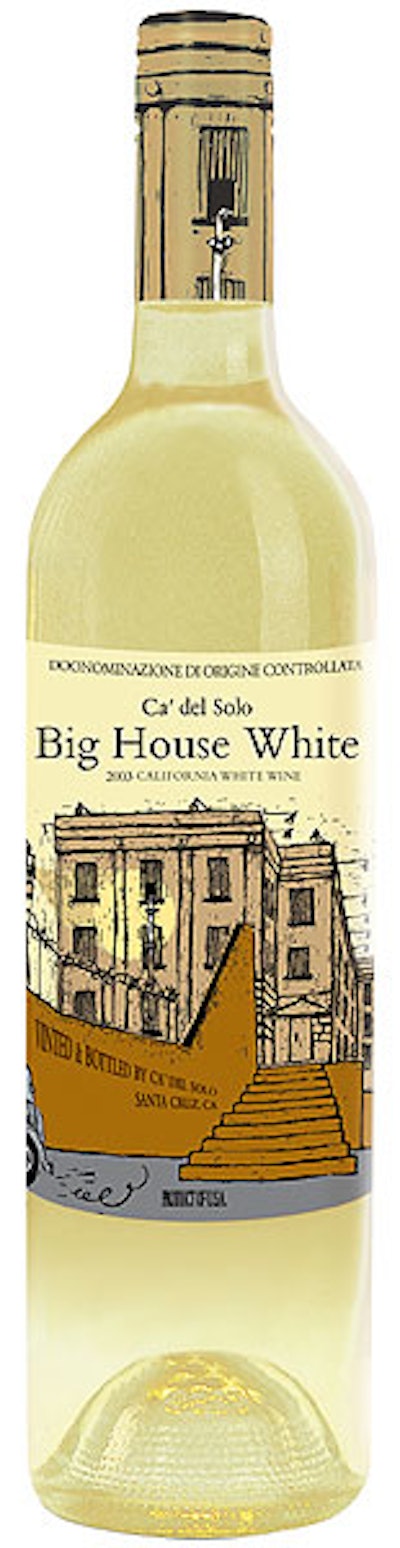

For those unfamiliar with his story, Grahm challenges the shopper with a delightfully offbeat approach to selling wine. Big House Red and Big House White are popular-priced ($9.95) wines that are blended from a variety of grapes, mostly Mediterranean in origin. Bonny Doon also markets more conventional varietals, from barbera to zinfandel. Although most of the winery’s offerings are inexpensive, some wines sell for more than $30/bottle.

The Big House varieties get their names and label illustration from the vineyard’s neighbor, the Soledad Men’s Correctional Facility. For these wines, Bonny Doon commissioned illustrator Chuck House to develop label graphics that portray a jailbreak. House, who is affiliated with Icon Design Group, also designed graphics for the new closure and redesigned the back label, calling attention to and explaining the reasons for the closure.

Or as Grahm puts it in his promotional copy: “Bring on the picnics, quilting bees, and orgies. You won’t need any specialized hardware to open [the wine bottles]. Opposable thumbs will do!”

As colorful and eccentric as Grahm is in his approach, Bonny Doon’s wines are regarded as highly drinkable, if somewhat offbeat. “Randall Grahm appears to have been on an enological ‘road less traveled’ from his earliest days,” says Eileen Fredrikson of Gomberg-Fredrikson, a winery consultant. “Often championing under-appreciated regions and grape varietals, his wines have been honored by critics, while also gaining a consumer-friendly image.

“Today’s young wine consumer is hip, experimental, brand conscious, and at the leading edge of a population bulge that will soon determine the direction of the American table,” Fredrikson continues. “Who better than Grahm and his excellent but irreverent Ca’ del Solo wines to push the limits of closure tradition?”

Eliminating cork taint

Among other approaches—including the use of synthetic cork—many wineries are looking for closures that will minimize or reduce problems of cork taint. This can be characterized as off-odor or off-flavor that results from oxidation. There are wide-ranging estimates of how pervasive cork taint is, from 2% to 6% of all cork-sealed wines.

Grahm estimates that as much as 10% of wines with cork closures may be tainted to one degree or another. It was just this issue that caused Pechiney to develop an organoleptically inert closure that would permit wine to age gracefully. Bonny Doon, in fact, uses Stelvin closures with either one of two special liners that contain polyvinylidene chloride barrier layers.

“We use the one gas-barrier liner for all wines that are either meant to be consumed short-term or meant to age for years,” Locke points out. “For red wines meant to be consumed in the mid-term, which tend to be reductive like barbera and zinfandel, we use a different liner, one that allows a microscopic level of oxygen exchange. These represent just about 10 percent to 15 percent of our production.”

Underscoring the winery’s commitment to the closure, Bonny Doon added a new closure applicator from Italy that represented a $100ꯠ investment.

Glass bottle supply

Not long after the Big House wines reached the market in 2002 with the screw cap, Bonny Doon realized the conversion had been successful. “That’s when we wanted to move on to our other wines,” Locke says. “Unfortunately, the real limiting factor was the availability of artful bottles to use with the Stelvin closure. That’s the main reason it’s taken us so long to reach a 98% conversion.”

In some cases, the winery worked with glassmakers to have threaded bottles produced specifically for them. However, when it involves having new molds made, Locke says the project to get new bottles can take the better part of a year. “To get the glass industry to respond to the demand for bottles with this finish, it took a couple of wineries, ourselves included, to have bottles made at our own expense,” Locke says.

“Now,” he adds, “we’re working with some of the very large manufacturers. At the same time, we’re also working with a small manufacturer in Italy that makes some of our specialty bottles.”

Along the way, Locke explains that the winery has done a lot of promotional work behind the change, and that continues to be ongoing.

“At this point, we think most people have accepted the screw caps, and people have now moved on to other issues,” Locke says. “At retail, our sales have gone so well that our problem is supplying enough wine. But there probably always will be some percentage of the market that will be resistant to cork alternatives, maybe five to ten percent. But it certainly hasn’t affected our sales.”