Recycling has rushed back to the front burner for many packagers this year as California lawmakers seek requirements to increase the use of recycled plastics.

Background of plastics laws

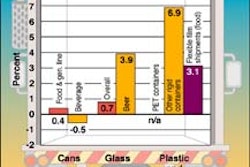

To meet the requirements of California's current law, SB 235, plastic containers had to reach a 25% recycling rate by 1995. If that rate was not met each year thereafter, manufacturers who use RPCs in sizes from 8 oz up to 1 gal would have to use 25% post-consumer recycled (PCR) content, or source-reduce packages by 10% between 1990 and 1995, or make the container reusable. Oregon had passed a similar law.

Oregon met its recovery rate in 1996, partly because of the state's bottle deposit law. However, California's Integrated Waste Management Board (CIWMB) has gone through much political wrangling over how to "count" the recycling rate. The "rate" was declared to be met for 1995. In 1996, industry was able to gain a food and cosmetics industry exemption from SB 235. But for manufacturers using RPCs, there are more challenges ahead.

California funded its own survey for 1996, which revealed that the 25% recycling rate was not met. Eventually, CIWMB randomly sent out letters to 500 manufacturers using RPCs, asking for compliance data. This May, the board ruled to take action against 99 companies for failing to comply with the law. The 25% recycling rate threshold was also not achieved in 1997, according to the state.

In addition to problems caused by attempting to enforce the law on thousands of manufacturers, the current law also requires companies to prove retroactive compliance to 1996 and 1997, via paperwork. Most manufacturers find this impossible to do. (Packaging World attempted to secure comments from some of the 22 California companies on the list of 500 singled out for enforcement by CIWMB. Of three companies reached, not one was aware of SB 235, and all said it would not apply to them.)

Back to the legislature

In 1998, CAW promoted AB 2555, a broad producer responsibility bill allowing industry to meet various utilization goals for plastics. The bill never got out of committee.

"Industry said that bill was too complex," says Bob Fredenburg, an aide to now State Sen. Wesley Chesbro (D-Santa Rosa), the bill's author. "So we decided to go back to the original law to keep it simple and targeted."

Lobbyists from the American Plastics Council (APC) attempted to place blame on local governments for not collecting data properly. This tended to turn lawmakers against industry, some observers said. Industry quickly moved to form an alliance to oppose the bill.

"The bill is unnecessary and unsafe," declared Roger Bernstein, chief lobbyist for APC. Despite 52 separate Food & Drug Administration letters of nonobjection for use of PCR in PET and high-density PE food applications, industry lobbyists argue there are no viable recycled-content options for manufacturers that use other resins, such as polypropylene, polyvinyl chloride and polystyrene. Bernstein also notes that if food companies are forced to use post-consumer recycled material, they run a product liability risk.

Consumer groups argue that 94% of all RPCs are either PET or HDPE, and post-consumer material is available for those containers. "Except for those containers included in the 'bottle bill' program, less than 14% of plastic containers are currently being recycled," says Rick Best of CAW. "SB 1110 would require the plastics industry, along with convenience food and cosmetics makers, to take responsibility for the growing problem of plastic packaging waste."

Despite strenuous objections, the bill moved through the Senate and on to the Assembly in July. Sen. Chesbro listened to the food and cosmetics companies' objections, attempting to address them by a separate section. Thus, after many amendments, the August 1999 bill:

* Left the recycled-content requirement for nonfood containers at 25%

* Kept the required overall recycling rate at 35% by 2003

* Required food and cosmetics containers to use 20% recycled material in their plastic containers by January 2001, and removed the option to use it directly in a closed loop. The rate ratchets up to 35% by 2003. Remaining options include using it in "other" packaging or products, or contracting with third parties to ensure such percentages are achieved.

Many complaints

"We're not making the 25-percent rate. Nobody is," says Dennis Greising with the Soap and Detergent Assn., New York, NY. "We certainly could absorb the paperwork easier than increasing recycled content. The 35% requirement would involve a whole new set of problems, like stress-cracking issues . . . There are a lot of companies [none part of SDA] that are out of compliance . . . I wish they would simply proceed with enforcing the existing law."

There are numerous complaints about the existing draft. For example, the new definition of "rigid plastic container" does not require the container to be "reclosable," which expands the law to a number of clamshells and other items, according to Lance Hastings of the Grocery Manufacturers of America.

"The [original] law is not meeting program objectives from 1991," says Hastings. "There is selective enforcement, and then we hear that we're not doing enough--all because CAW wants more plastics recycling. We see the issue through different lenses." He says industry will defeat the bill if it stays in its current form.

Yet, other observers, even some in industry, admit that the cities and CAW may have the votes to pass a bill in 2000.

In a PW interview, Chesbro aide Fredenburg revealed that the senator knows there are problems with the current bill. "No, it's not going to pass in its current form . . . it needs to be fixed. We need to look at broadening the markets for recycled plastics. It should not just affect packagers."

Fredenburg made it clear there are two issues Sen. Chesbro will not give in on: One, the bill has to include food and cosmetics containers because they represent 60% of RPCs; and two, the bill has to push packagers to seek more markets for recycled plastics. He points out that the amended version of the bill does not even require closed-loop use of recycled plastics in food and cosmetics containers. On the other hand, critics say the amendment only reduced the number of compliance options.

Even though no companies have offered to send engineers to Sacramento, "we're going to go around the lobbyists" this fall, Fredenburg says, to seek out opinions of technical experts from a wide range of companies in different sectors.

Will a mandate be needed?

"We need some stability," explains William O'Grady, general manager of PE recycler Talco Plastics, who speaks only for himself. "If recycled is less expensive than virgin, it's a lot easier to go out and educate people to use it." But most plastics users today do not see PCR as a reliable, cheap alternative.

O'Grady stresses that quality of the recycled resin is not the issue it used to be. Today, he says, recyclers clean the material far better than five years ago. "There has to be a driver out there to encourage expansion. Legislation is not the best way to get the desired result, but it's the only avenue we know."

Whether a new mandate emerges from the governor's office next year or not, companies using plastic packaging are unlikely to escape without absorbing additional public blows to their image.

Michele Raymond is publisher of State Recycling Laws Update and Recycling Laws International. Her company, Raymond Communications, is co-organizing the next "Take it Back!" conference, to be held in Los Angeles, CA, Feb. 28 - March 1, 2000. The international conference will feature a full debate between all parties and sectors on the issue of extended producer responsibility. Her company can be reached by phone at 301/345-4237. Its Web site: www.raymond.com.