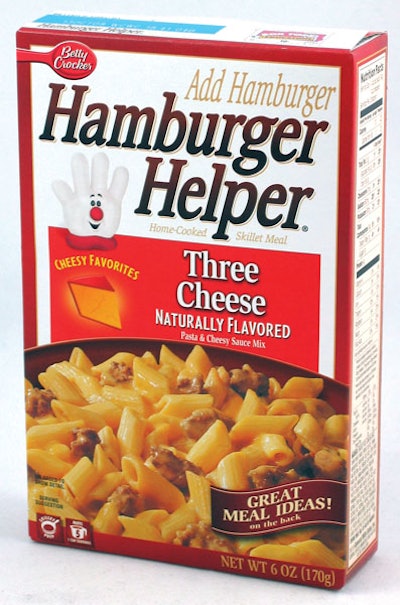

Look at your product and package holistically. General Mills discovered that innovation in manufacturing could lead to lower costs in packaging. The company’s Hamburger Helper brand is a case in point. General Mills evaluated both the product and the package, and then reshaped the noodles.

That brought about a 20% reduction in package size, or 890,000 lb of paper fiber annually—with no adverse impact on product quality or consumer perception.

“The company increased the density of the pasta shapes so they could be packed more tightly and in a smaller box,” explains General Mills Corporate Public Relations Manager Kristie Foster. “We also reduced the number of pouches in each carton.”