When it comes to fitting copy onto bottle labels, the smaller the bottle, the bigger the problem.

Tender Corp. of Littleton, NH, faced a space challenge for its Ben’s 30 brand of insect repellent product marketed in Canada. The bilingual copy for directions, precautions, first aid, disposal, and toxicology information requires extensive on-package real estate. Then things became more challenging: As of November 2006, the Canadian government required that consumer products be labeled both in French and English in the same size format.

Unfortunately for Tender, the Ben’s Canadian spray bottle measures just 1.75 inches by 2.5 inches and holds 1.25 oz (37 mL) of product—the same bottle it uses for the U.S. market.

“When you’re dealing with small packages like our little Ben’s product bottle, it’s hard to get all that information on the label and still get it to look like the product brand without having the label be just a bunch of text,” says Vern Schrum, the product manager for regulatory affairs and product management for Tender’s Canadian product line. “The main thrust behind the whole project was to find a label configuration that would allow us to comply with Canadian regulations, yet still go to market with a brand identity that looked like the Ben’s product we distribute in the United States.” Tender found its answer via the FlexVision™ extended-text label from WS Packaging Group (www.wspackaging.com) and its MultiVision® label line.

Tender had been a WS Packaging customer for more than 10 years when it brought the challenge to the company’s attention. Up to that point, the product was sealed inside a paperboard-backed blister pack with die-cut holes for double- or single-peg display merchandising. The pack measured 4” by 6.5.” The bottle had two labels. The front was in English and carried the Ben’s name, while the back label carried the French text. The front label was 2.6-mil white polypropylene and the back label 2-mil clear polypropylene.

“Pesticide and hazardous materials regulations require a lot of text, so we were only able to put some of the information on the bottle,” Schrum says. “The rest had to go on the paperboard card. But that put an added burden on the consumer because they had to keep track of the card for reference. We wanted a solution that would allow us to eliminate the card, but still meet the government requirements.”

The switch to the FlexVision extended-text label, which features a flexible, film-based construction engineered exclusively for plastic tubes and bottles, provided an easy solution. The patented, resealable label conforms to the curved surface and tolerates wet environments, especially the harsh conditions of the repellent ingredients.

Solvent-resisting construction.

Among the biggest issues Tender faced was a label substrate that would withstand exposure to the insect repellent chemical DEET (N,N-Diethyl-meta-Toluamide). Ben’s 30 contains a formulation that is 30% DEET. “DEET can dissolve the adhesive, the ink, and the substrate, so it creates quite a harsh environment from a packaging standpoint,” Schrum says. “Yet we had to make sure the label would outlast the life of the product.”

The FlexVision label is composed of three panels: a top layer with a front and back is hinged to a base panel that is adhered to the bottle. The top panel is 2.6-mil white polypropylene printed in three colors and over-laminated with 1.4-mil PP to protect it from the DEET ingredients. The backside of the top panel is printed in black. The base panel is 2-mil clear PP with black ink and a varnish. The finished label measures 1.56 inches by 2.0 inches and includes a .25-inch hinge. To ensure the label remains intact, FlexVision labels are tested to reseal with a shelf life of at least two years.

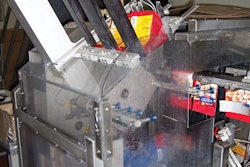

Provided in roll form, the new FlexVision labels are applied seamlessly using Tender’s workhorse labeler, which has helped affix its labels for 10 years, according to Schrum.

“By eliminating the paperboard card, we’re able to get more of our product on the shelf in less space, and that has really given us more flexibility to communicate without impeding our brand identity and positioning,” says Schrum, who estimates that 50% more product can now be shelved in the same space as with the blister-packed format. “It also makes it possible for us to have the product on the shelf with a big chain or at the checkout counter of a small mom-and-pop store.” He says retailers can position the product with English or French copy forward.

Marketing aside, Tender has also implemented a sustainable packaging solution by reducing the overall environmental impact of the product packaging.

“With FlexVision, we’ve made things simpler and easier for the retailer, and better for the environment,” Schrum says. “We’ve also enhanced the consumer experience by putting all the product information literally at their fingertips.”

Introduced in spring 2006, Ben’s 30 insect repellent is priced around $3.50. Ben’s 30 is currently available only in Canada in the new label format, however Schrum says Tender will consider other applications of the FlexVision label in the future.

—Rick Lingle

For related articles visit packworld.com/chemicals