This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

With this option, WLS’ VR-72 labeler can be programmed to achieve a new label height for an entire batch or dynamically adjust the height of each label for every individual container to improve production efficiencies, reduce label inventory and/or maximize shelf appeal.

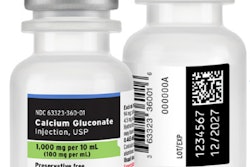

Capable of speeds in excess of 600 containers/min, the VR-72 applies pressure-sensitive, wrap-around labels made of paper or film to cylindrical, free-standing packages. This fully servo-driven, continuous-motion labeler provides high throughput, accurate label placement, low maintenance and quick changeovers. When equipped with the height-adjustable labeling option, the VR-72 primarily runs vials and bottles containing liquid pharmaceuticals, biotech products, nutraceuticals, personal care products, cosmetics and other consumer goods.

This option is ideal for products that need a printed fill line to be positioned on the container at a particular height, such as pharmaceuticals in which the consumer is going to pour in another solution up to the designated fill line. Placing that fill line on the primary label and changing the label height for each product run allows manufacturers and contract packers to utilize the exact same printed label across multiple batches to minimize label changes, reduce label inventory and eliminate the need for downstream printing processes.

It is also ideal for manufacturers and packers with products that present minor variation in fill level. Customers can maximize shelf appeal by dynamically adjusting the height of each label on every single container, relative to the specific fill level. To change the label height dynamically, the VR-72 utilizes a camera to inspect the fill level of each container, quickly identifies the perfect label height based on that fill level and adjusts the conveyor position, as needed.

WLS can equip the VR-72 with an optional label inspection system and reject device to ensure each label’s content and/or placement on the package are accurate.

While the height-adjustable labeling option is designed for liquid products in vials and bottles, the standard VR-72 can apply labels to a wide variety of cylindrical packages containing solid doses, vitamins, injectables, medical devices and more. The labeler can accommodate different types of code printing methods to print lot numbers, expiration dates and/or 2D codes, with or without serialized data.

The VR-72 changes over quickly, handling a new product size in as little as fifteen minutes with no tools required, a single size part and integrated HMI recipes.