The conveyor system’s equipment features powder coated/anodized aluminum and powder coated steel construction. Customers can achieve standard variable speeds up to 100 fpm and optional speeds up to 200 fpm. In addition, the solution includes a smooth belt with V-guide to prevent tracking issues.

Conveyor solutions are available with printhead, photocell, and encoder mounts. Adjustable guides can help improve efficiency for operations with variable case sizes.

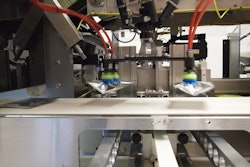

Smooth material handling helps optimize print quality and limit operator intervention to help mitigate errors.

All guide rail brackets, encoder mounts, and printhead mounting plates clamp onto the side of the conveyors with a patented dove-tail design. Customers have no need for drilling or tapping holes; all accessories are easily adjusted with an Allen wrench. Accessories can be slid in the dove-tail groove or loosened enough to be removed and placed in any available spot on the conveyor. The conveyor height is adjustable from 24- to 36-in.

The material handling solutions can be used with many current case coding printers, label printer applicators and thermal ink jet systems.