Located in Essex, MD, Tessemae’s All Natural is a salad dressing and condiment company founded by brothers Greg, Brian, and Matt Vetter, who started with a simple dressing recipe created and used by their mom throughout their childhood. Says Matt Vetter, “Our commitment to healthy eating and living is the core of our mission of providing consumers with simple, yet delicious food made with only real ingredients.”

Tessemae’s fresh salad dressings were launched in 2009 and are now sold at a range of retail grocery chains across the country, including Whole Foods, Kroger, Safeway, The Fresh Market, and Costco. Products include 13 salad dressings and 11 condiments, including mayo, mustard, and ketchup, among others.

Available in both bottles and condiment pouches, Tessemae’s salad dressings are filled at its 36,000-sq-ft manufacturing plant in Essex. The facility operates two packaging lines: an in-line bottle filling system, and a Prodo-Pak vertical form/fill/seal line for the sachets.

Until recently, Tessemae’s used thermal transfer overcoat equipment to code its bottle labels and its sachets with Best By date codes. However, in early 2015, Jeff Fisher, Regional Sales Professional Packaging, Food Segment, of equipment supplier Veritiv Corp., introduced Tessemae’s to thermal ink-jet printing, a cost-effective, low-maintenance alternative to their existing coding method. The company soon adopted this technology for both of its packaging lines.

Thermal ink-jet offers many benefits

For its bottle filling line, Tessemae’s installed a Veritiv-supplied iJet independently operating thermal ink-jet print head from AT Information Products. The unit prints Best By dates at speeds to 40/min on high-gloss labels before they are applied to the salad dressing bottles.

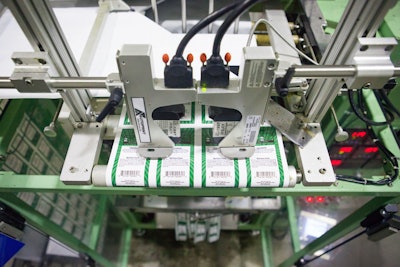

The vf/f/s pouch line is now equipped with ATIP’s X4Jet print controller with two single ATIP Autoprint print heads that print on four pouches simultaneously. Pouches measure 3 x 5.5 in. and are constructed of 48-ga PET/four-color print/adhesive/0.025-mil EVOH LLDPE. Using solvent-based ink, the print heads add Best By codes to the preprinted sachet rollstock at 160/min.

Both the iJet and X4Jet are programmed using ATIP’s iDesign software for label formats and database connections. Says Matt Vetter, “In a matter of seconds, we can create a new message and send it to the printer for immediate use. Virtually all barcode types are supported, including all linear and 2D codes.”

ATIP’s equipment is based on HP thermal ink-jet technology, which offers a number of benefits. Among them, 300-dpi barcode-quality printing; a patented Click’n Print cartridge replacement system that makes cartridge installation clean and easy; low operating costs; and maintenance-free operation.

“Thermal ink-jet’s sealed, cartridge-based system makes ink changeovers quick and easy, and helps eliminate the possibility of spills or other maintenance issues that require servicing,” says Matt Vetter. “The cartridge is also very easy to clean. We simply wipe the print head with a soft, fiber-less cloth. No solvent additives are needed.”

Change is easily justified

Since installing the new printers, Tessemae’s has realized a 60% savings on bottle label coding, “which was more than enough to justify the technology change,” says Matt Vetter. The company has also increased its uptime and has improved the clarity of the printing on its labels and pouches.

“The ATIP coders look and perform like industrial coders; the printers have industrial casing that looks indestructible,” says Vetter. “We put them to the test on our packaging lines, and they just keep running and running, with minimal servicing and virtually no downtime.”