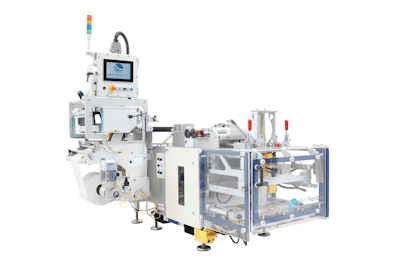

Demonstrated at the show, the new Hayssen Mini vertical form/fill/seal bagger from BW Flexible Systems allows users to run either paper or film, with a changeover time of less than 10 minutes between materials. Explains Dan Irod, Director of Business Development for BW Flexible Systems, the bagger is the fulfillment of a request from one of the company’s customers seven years ago who wanted to switch from paper to plastic for 100% of its bags. “Until that moment, we had never evaluated the possibility of working with paper, so it was a totally new thing for us,” Irod says.

In developing the system, BW Flexible collaborated with materials suppliers to find a paper-based web material that could seal on its equipment. Options include a paper web with a peelable film layer that can be removed, allowing the paper to be recycled or composted, or paper with a thin layer of PE for barrier.

Simultaneous with finding a paper that could be sealed on BW Flexible’s equipment was the development of a machine that could handle the paper. Says Irod, running paper on a vf/f/s machine requires a different film path and unwinding of the material. “You have to control the pulling of the web and also the tension of the packaging materials,” he says.

In engineering the machine to meet new packaging material requirements, however, Irod said he wanted to be sure that if the sustainability winds changed (again) with greater recycling of plastic, that customers would have the choice of running either material. “That was one of the challenges I brought to my team,” he says, “just to always be able to take a step back and retrofit the machine with different tooling that allows for the use of plastic.”

Another notable feature of the machine is its small footprint: The Hayssen Mini is just 1.3 m high, or approximately 4 ft. Shares Irod, sustainability isn’t only about the material being run on the machine, but also a machine’s electrical consumption, the number of air compressors it uses, and its footprint. “As I like to say, the Hayssen Mini will allow a small customer to work even in a garage,” he says. “It’s not going to be a garage definitely, but that’s the concept.”

The Mini also offers in-line printing with water-based inks as an option.