Some important lessons have been learned along the way, guiding the design and execution of a study that will provide valued information to multiple stakeholders and prove worthy of the investment of time and resources.

If you don’t know, or don’t want to follow the rules...don’t start. Life-cycle analysis is an expensive, time-consuming process, and its value depends entirely on the credibility of the information it yields. That’s why setting appropriate goal and scope, system boundaries, and functional units to be measured is the most important step in LCA planning.

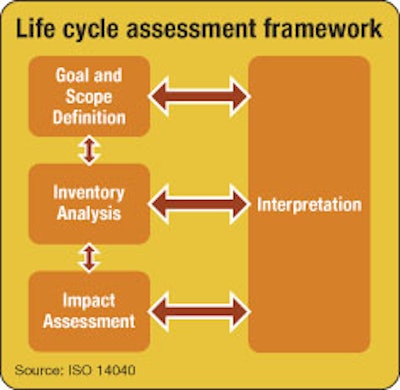

Life Cycle Assessment, first developed in the late 1960s, focused initially on waste and energy. In 1996-2000, LCA guidelines were standardized by ISO in its 14040 series and have been used by thousands of companies across a range of sectors to guide product and process improvements. Today, LCAs are increasingly being used to inform public policy, assist in research and development, aid in decisions surrounding waste management, food vs. fuel, bio-fuels, renewable energy, and public policy such as WEEE/RoHS & LEED. Numerous commercial software and databases are already available, so there’s no need to “start from scratch” in developing methodologies or gathering data in many areas.

Overview of an LCA Study

Real-world execution of a comprehensive LCA Study includes:

• Goal & Scope Definition—Determining scope and system boundaries

• Life Cycle Inventory—Data collection, modeling & analysis

• Impact Assessment—Analysis of inputs and outputs using indicators

• Interpretation—Sensitivity analysis, Monte Carlo analysis, dominance analysis, etc.

When planning an LCA, it’s important to think the process all the way through, and commit to key principles to assure the study’s value, including:

• being open, objective, and transparent. This means openly defining a study’s parameters, scope and boundaries, and assumed values. Without transparency, results are meaningless in making comparisons or claims and can be misused. An open and transparent process assures accountability for reporting of results;

• reaching consensus surrounding what you want to do; and

• conducting a review by third-party LCA experts and publishing results. ISO guidelines call for such measures to assure objectivity, relevance, and credibility.

Goal & Scope: The most important step in LCA

Carefully defining the goal and scope of an LCA is crucial to gaining meaningful information and to controlling cost. The corrugated industry established the scope of its study by considering:

• LCA can be focused on internal and/or external uses, eco-design, to support marketing, comparison of products, or to support policy;

• Stakeholders, both internal and external; and

• LCA boundaries, including process scope, functional unit, reference flow, time frame, geographical boundary, data requirements, selection of impact categories, and allocation decisions.

Goals of the U.S. Corrugated LCA Study

Established goals for the Corrugated Packaging Alliance LCA study include:

• Construct a core LCI data set for corrugated packaging

• Respond to marketplace requests (e.g. Wal-Mart, etc.)

• Identify relevant impact indicators and their key mechanisms for this industrial sector

• Conform to ISO 14040 series, necessary to support comparisons

• Maintain confidentiality of data sources

• Allow member companies to maintain their own disaggregated data to allow for private comparisons, benchmarking to industry average data

• Build knowledge within industry members on how to use LCA information

• Collect data in formats compatible to support potential inclusion in databases (e.g. U.S. LCI data set, commercial database packages), and to support other uses, communication strategies, etc.

• Establish a context that enables brainstorming of applicable scenarios in the future

• Modular structure to allow for streamlining of initial analysis and future expansion of analysis

• Establish system boundaries and other rule sets necessary for comparable studies that can become industry standard

• Approach the international community for comment. In scoping its study, the CPA determined that its Life Cycle Analysis would be directed to internal audiences (member companies) as well as to potential external stakeholders including retailers, CPGs, national data bases (such as MERGE and the U.S. LCI data base), NGOs (such as the Sustainable Packaging Coalition), EPA, the international corrugated community, academics, LCA practitioners, software providers, and packaging professionals who are required to understand and use the information in decision-making. Many of these audiences require specific formats to meet their needs for scorecards, data templates, ISO standards, U.S. LCI data base, etc. The corrugated industry is also requiring a final report that is explained in “plain English” for maximum communication value. All the required formats were considered in the initial study design.

Why Do an Impact Assessment?

A life-cycle inventory (LCI) quantifies the inputs (raw materials, energy, etc.) and outputs (emissions, waste, toxicity, etc.) generated by a process or industry. This information is vital but can be misleading without a full impact assessment. For example, 1,600 kg of CO2 shown in a sample inventory seems highly significant compared to just 2.5 kg of CFC 11; but an impact assessment shows the smaller amount of CFC would have a far greater negative effect on the environment. Without analyzing the actual environmental impact, one might wrongly conclude that the CO2 was a more important reduction goal. Inventories provide important numbers, but impact assessment tells you what matters most and becomes a meaningful baseline for improvement.

It is equally important to identify the best practitioner for conducting the corrugated LCA and engage reviewers from key stakeholder groups. Check references and make sure the experts you engage are committed to the same level of transparency and credibility that you’ll need to defend your findings. The corrugated industry retained Five Winds International, a world leader in life-cycle analysis that emphasizes these critical ground rules in its scientific, expert-reviewed approach, and deliberately steered clear of firms whose past work has fallen short. Retaining a broad-based panel of LCA experts is critical to ensure the study’s goal and scope, system boundaries, functional units, etc., all meet the requirements of the ISO 14040 LCA framework as well as the informational needs of external stakeholders, helping optimize value.

When it’s done, an LCA may prove to be the start of a never-ending journey. Properly used, it is an investment in baseline understanding that helps an industry or an individual company measure changes. It also serves as a comparison tool for industry improvement and as a benchmark against competing products/materials. In addition, it will provide tools for the corrugated industry to use in performing consistent calculations and allows our members to uniformly respond to customer inquiries.

Summary

• Begin with the end in mind

• What is important to you and your audience(s)?

• Follow ISO 14040 guidelines

• Assures you’re open, objective, and transparent

• Provides a credible basis for communications and comparisons

• Choose the best LCA practitioner and reviewers

• Use the results to improve your industry, company or product

Sustainability and life cycle approaches are strategic bridges to prioritizing and implementing sustainable initiatives that will create value for key stakeholders. That’s been the guiding principle in planning a useful LCA for the corrugated industry. In addition, the CPA will work through the EPA, NGOs, and the academic community to replace the less accurate and considerably dated information that is being used by broad audiences to judge products. And lastly, we will work though the International Corrugated Case Assn. (ICCA) and its newly established Sustainability Committee, to persuade the international corrugated community (the U.S. is already aligned with Europe) to utilize common methodologies—including goal, scope, boundaries and functional unit—to allow for meaningful comparisons in what has become a global marketplace for corrugated containers.

Dwight Schmidt may be reached at [email protected]. Related Web sites: www.fibrebox.org, www.corrugated.org, www.afandpa.org, www.aiccbox.org