This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

In modern production, every minute counts. Automated cleaning processes not only ensure greater process reliability, but also enable fast product changes without time-consuming conversion work. This reduces downtimes while maintaining the same high production output. Flexibility and efficiency are no longer mutually exclusive with the ViscoTec vipura-PUMP 10T.

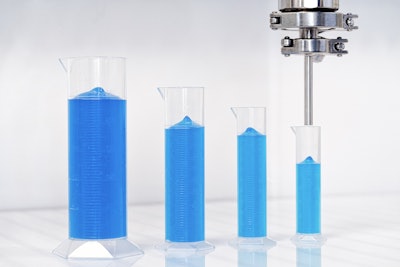

The compact design of the vipura-PUMP 10T makes it easy to integrate the dosing and filling pump into complete systems. The option of automated cleaning means that nothing stands in the way of a quick batch change. It is suitable for a wide variety of materials to meet your requirements: Different viscosities, chunky and even abrasive materials can be dosed. The special dispensing geometry ensures precise dispensing results and short cycle times and works non-destructively even with lumpy materials up to 20 mm in diameter. The dispensing volumes are flexibly adjustable, from 20 to 500 ml or higher, depending on the cycle output. These quantities can be precisely dosed and filled depending on the application and to suit the specific requirements.

Easy handling of the vipura-PUMP 10T

Cleaning is quick and easy via a CIP connection. Automated cleaning increases process reliability.

The vipura-PUMP 10T is suitable for dosing and filling various materials: For food and pharmaceuticals as well as for household products and cosmetics. Common applications include tubular bag filling of chunky sauces or marinades, but also pet food or shower gel, detergents, toothpaste, creams, etc. And thanks to automated cleaning, fast batch changes can be implemented smoothly in future. Reduce downtimes, not your production output!

Watch the video about the dosing and filling pump here: https://youtu.be/EE24CdVnCJM