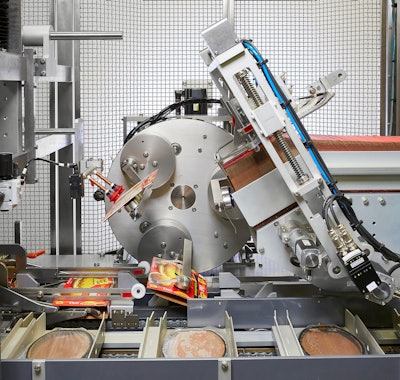

PMI KYOTO’s all-servo driven cartoner has a compact design, providing a small footprint and making it easy to integrate. It is designed and built to FDA sanitary standards and features heavy-duty, fully welded stainless steel washdown construction. Quick and simple changeovers are performed at the touch of a button on the HMI making it ideal for a variety of SKUs and suitable for CPGs and contract packagers. With built-to-last, quality construction and materials, this system features full-height guard doors with interlocked stainless frame. The system can run cartons or sleeves at speeds up to 240/min.

Also ideal for CPGs and contract packagers is the system’s flexibility to ramp up or down production as needed. For smaller runs or lower output, a hand-load option is available. When production needs to increase, simply add on a robotic infeed section for higher speeds and added efficiency.

“We’re excited to bring a flexible and efficient solution to the market,” said Branko Vukotic, PMI KYOTO President. “By offering a washdown horizontal system for frozen foods and dairy, we are able to address the needs of additional industries and bring more value to our customers.”

Additional features include a high-speed servo-driven rotary carton placer with pre-break, articulating product buckets with barrel cam pusher heads, servo flap tuckers with cycle stop mode-positive flap closing device, Nordson hot melt glue system and an Allen-Bradley system control platform and HMI. -PW