Manufacturers using flexible packaging require a thermal transfer printing solution that is quick, simple and virtually error-proof, allowing them to spend more time focusing on the critical aspects of their business, such as improving production line efficiency and reducing overall operating costs. In response to this need,Videojet has developed the DataFlex 6530 107mm and 6330 32mm, which are part of the Videojet DataFlex TTO range – designed to give customers a more productive operation. These new Videojet printers embody the latest technology to help further improve uptime and drive productivity, quality and efficiency.

The DataFlex 6330 32mm comes with revolutionary Videojet iAssure™ technology, a feature also standard in its 53mm TTO sister models. This innovative technology is a built-incode quality checkerthat automatically checks for code quality and position and provides a warning when common code defects are detected. Users can then decide whether to stop the line to correct the fault, thus reducing the need to scrap or rework product. This allows operators to focus on other areas of the production line.

“Videojet iAssure technology helps our customers to reduce product waste and rework by automatically checking every code with no additional hardware, installation, or training,” said Heidi Wright, business unit manager for Videojet Technologies. “When we researched and evaluated the customer requirements for an easy, cost effective code checking solution, we initially considered some form of traditional vision system approach. When we took our thoughts back to the market as part of our VOC validation, customers told us that they wanted this capability to be integrated into the printer, with no additional setup requirements or adjustments because they have enough to consider without training their operators to be vision experts. iAssure technology makes automatic code checking so simple. When a pre-set number of code defects are detected, it alerts operators by stopping the line or rejecting products with poor code quality. It also provides on-screen recommendations for production line adjustments that can help to improve the code quality. No other Thermal Transfer Overprinter in the market can do this.”

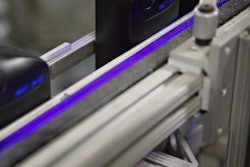

The DataFlex 6530 107mm and 6330 32mm printers are easy to integrate into typical production lines. Featuring a design that is modular and compact, they offer manufacturers and OEMs the flexibility to choose how they integrate the printer. The power supply can be placed with the controller or separated and mounted inside the packaging machine cabinet. Industry standard mounting features help to simplify installation and improve operator accessibility and interaction.

Ideal for manufacturers who want fewer components exposed in a production environment, the printers feature fewer cables and can be controlled through the packaging machine’s web interface, eliminating the need for the Videojet controller. This enables manufacturers to have a single point of control for both the printer and packaging machine.

Designed to withstand tough production lines, the DataFlex 6530 107mm and 6330 32mm are airless, all-electronic printers, eliminating the need for high-quality and expensive compressed air. The airless design helps to reduce operation costs, provide more precise control of the printhead movement and increase throughput by 25 percent. Operators no longer need to adjust the air pressure required when trying to improve print quality, which can increase the potential for premature head wear.

The DataFlex 6530 107mm and 6330 32mm printers also feature an industry-leading quick-change cassette that is designed to deliver both excellent ribbon efficiency and fast ribbon replacement, helping to maximize production uptime. With up to 1200m in ribbon capacity, manufacturers can achieve more throughput between ribbon changes.

“Our customers need solutions that deliver quick, simple and virtually error-proof operation. Now offering a wider variety of printhead sizes that incorporate industry-leading features, this TTO series, including the new 6530 107mm and 6330 32mm printers, does just that,” said Wright.