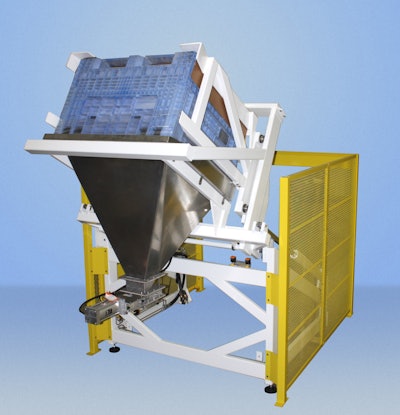

Dust-tight container discharge system

Pour hood includes an air actuated slide gate for material flow control. Unit features a continuously welded tubular steel frame, rigid conduit and hydraulic lines, and a carbon steel NEMA 4 control enclosure. Unit includes safety caging and two-hand controls for enhanced operator safety, and is painted FDA white epoxy for easy equipment cleaning.

Companies in this product

Videos from Material Transfer