This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The new system operates with Eagle’s SimulTask™ XE image analysis software, an advanced traceability tool ensuring compliance with Hazard Analysis and Critical Control Point (HACCP) principles. The new system will help food manufacturers expand their businesses on a global scale by enabling compliance with international food safety regulations and retailer guidelines. HACCP is a management system that addresses food safety through the analysis and control of biological, chemical and physical hazards from material production to manufacturing, distribution and consumption of end products. Mandatory for the meat, seafood and juice industries, HACCP is regulated by the United Stated Department of Agriculture (USDA) and the Food and Drug Administration (FDA). The Eagle Pack 240 XE enables food manufacturers to comply with HACCP guidelines and establish reliable and fully documented product inspections.

The new Eagle system can support a “supermarket package”, a software and hardware option offering enhanced control measures required by leading supermarket brands for product safety. This feature enhances reject monitoring functions to reduce the possibility of human intervention, increasing security levels in production lines. The software allows food manufacturers to compete on a global level by providing them with the inspection tools to accommodate leading international supermarket brands. The Eagle SimulTask™ image analysis software is the basis for the company’s "set and forget" line of operator-friendly x-ray inspection systems. Its fully customized interface simplifies product set-up to facilitate changeovers, reduce downtime and increase flexibility with the product inspection process. It also includes various operator log-in levels, allowing access rights only to designated users to prevent operator error and further enhance security.

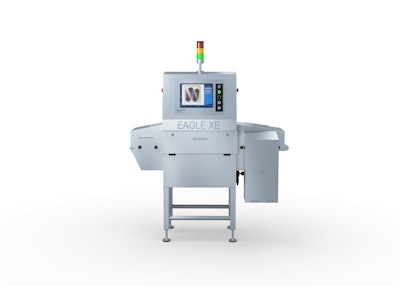

The Eagle Pack 240 XE is the latest addition to the Eagle Product Inspection line of product inspection systems, which detect and reject foreign body contaminants such as metal, glass, stone, bone, plastics and rubber in food products. Its high sensitivity detection levels are suitable for a broad range of packaging materials and shapes for the confectionery, bakery, ready meal and dairy sectors.