Switchback Group's new robotic case packer combining their flexible pack handling expertise, an ELAU delta 2 robot mechanism and

Switchback Group (PACK EXPO Booth S-563) may not be a household name –

yet. But their approach to integrated, robot-enabled packaging systems

delivers just what the market is asking for.

Switchback’s David Shepherd has assembled, through acquisition, a lineup that includes tray formers, erectors, closers, cartoners, sleeve wrappers, labelers, case packers, tapers and gluers. They’re focusing their attention right now on robotics in an important market segment: handling and packing poly bagged foods and other products.

Everything depends on the infeed

Whether you’re cartoning or case packing, you always collate products,” says chief engineer John Zweigle. “Everything is about the infeed of product. Only now it’s robotic.

“It can be stand-up pouches, cartons or bags. It could be shingling or a matrix of bottles that requires rotation for orientation. You could be collating for multiple pack patterns, layers or packing bags on end. Everything depends on the infeed.”

Enter the ‘packaging systems provider’

Switchback handles what it calls ‘soft integration,’ which means all the transfers and manipulations from product assembly through primary and secondary packaging. That includes the conveying and the HMI integration of the process.

It is also means robotic handling, which provides greater flexibility, simplified mechanics and faster changeovers compared to conventional ‘hard’ or fixed automation.

Switchback is what a new ARC study calls ‘packaging systems providers’ rather than traditional, narrowly defined OEM machine builders. ARC recommends that packagers seek out this capability.

Robotic capabilities

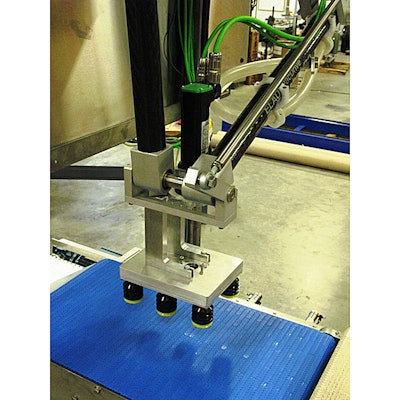

Switchback’s latest development is an extremely compact delta 2 robot case packer that debuts at PACK EXPO. It’s initially targeted at handling flexible packages, so the show machine uses dual durometer vacuum grippers. But it can be equipped with mechanical tooling as well, for specialized tasks such as grippers for jars and pneumatic cylinder equipped tooling for gabletop cartons.

The new robot runs up to 45 cycles per minute or up to 55 lb. payloads. It can be fitted with a variety of infeeds and side guides. Changeover is menu driven from the digital controller, so takes only 3 to 4 minutes. Options include quick-change tooling, and all Switchback tooling is ergonomically designed.

Partnering with Schneider Electric, ELAU Packaging Solutions

To rapidly develop a robotic orienting and case packing solution customized to Switchback’s focus, they partnered with Schneider Electric and ELAU Packaging Solutions (PACK EXPO Booth E-6413).

First, ELAU offers ready-to-run delta robot arms and a robotic library with software objects that automatically perform all the kinematic transformations needed to program robotic motion. This means that Switchback engineers could concentrate on their own areas of expertise and still deliver an uncompromising robotic solution..

It is true robotic motion, calculating the smoothest, most direct and fastest path. The arm does not move from point to point, so the robotic motion is never jerky. Software automatically prevents accelerations from generating too much g-force and dislodging product from the gripper.

Schneider’s Magelis HMI is integrated with ELAU’s purpose-built packaging automation system, supporting the ‘soft’ integration deliverable. Schneider also delivers the practical advantages of a single source for the complete electrical solution, from safety to sensors to VFDs and I/O.

About Switchback Group

Switchback Group offers some of the most innovative and flexible End Load Cartoners and Case Packing equipment on the market. End Load machinery includes Automatic, Semi-Automatic, Intermittent Motion, Sleever and Hand Load style Cartoners. Wraparound, End Load and Robotic Top Load Case Packers are offered for packaging product into corrugated cases. Whatever the application in chipboard and corrugated, Switchback Group will offer a solution.

www.switchbackgroup.com

About ELAU packaging solutions

ELAU, Schneider Electric’s packaging specialist, equips over $1 billion worth of packaging machines annually. Currently, over 40,000 purpose-built ELAU packaging automation systems are deployed in machinery worldwide.

Through ELAU, Schneider Electric is the only controls supplier with a dedicated business unit focused exclusively on the automation of packaging machinery.

The market demands packaging operations that are more flexible, efficient and sustainable to fulfill marketing, supply chain and global business strategies. ELAU innovations have enabled a revolution in mechanical, software and hardware modularity to deliver these agile packaging systems.

For more information, visit www.elau.com or email [email protected].

Switchback’s David Shepherd has assembled, through acquisition, a lineup that includes tray formers, erectors, closers, cartoners, sleeve wrappers, labelers, case packers, tapers and gluers. They’re focusing their attention right now on robotics in an important market segment: handling and packing poly bagged foods and other products.

Everything depends on the infeed

Whether you’re cartoning or case packing, you always collate products,” says chief engineer John Zweigle. “Everything is about the infeed of product. Only now it’s robotic.

“It can be stand-up pouches, cartons or bags. It could be shingling or a matrix of bottles that requires rotation for orientation. You could be collating for multiple pack patterns, layers or packing bags on end. Everything depends on the infeed.”

Enter the ‘packaging systems provider’

Switchback handles what it calls ‘soft integration,’ which means all the transfers and manipulations from product assembly through primary and secondary packaging. That includes the conveying and the HMI integration of the process.

It is also means robotic handling, which provides greater flexibility, simplified mechanics and faster changeovers compared to conventional ‘hard’ or fixed automation.

Switchback is what a new ARC study calls ‘packaging systems providers’ rather than traditional, narrowly defined OEM machine builders. ARC recommends that packagers seek out this capability.

Robotic capabilities

Switchback’s latest development is an extremely compact delta 2 robot case packer that debuts at PACK EXPO. It’s initially targeted at handling flexible packages, so the show machine uses dual durometer vacuum grippers. But it can be equipped with mechanical tooling as well, for specialized tasks such as grippers for jars and pneumatic cylinder equipped tooling for gabletop cartons.

The new robot runs up to 45 cycles per minute or up to 55 lb. payloads. It can be fitted with a variety of infeeds and side guides. Changeover is menu driven from the digital controller, so takes only 3 to 4 minutes. Options include quick-change tooling, and all Switchback tooling is ergonomically designed.

Partnering with Schneider Electric, ELAU Packaging Solutions

To rapidly develop a robotic orienting and case packing solution customized to Switchback’s focus, they partnered with Schneider Electric and ELAU Packaging Solutions (PACK EXPO Booth E-6413).

First, ELAU offers ready-to-run delta robot arms and a robotic library with software objects that automatically perform all the kinematic transformations needed to program robotic motion. This means that Switchback engineers could concentrate on their own areas of expertise and still deliver an uncompromising robotic solution..

It is true robotic motion, calculating the smoothest, most direct and fastest path. The arm does not move from point to point, so the robotic motion is never jerky. Software automatically prevents accelerations from generating too much g-force and dislodging product from the gripper.

Schneider’s Magelis HMI is integrated with ELAU’s purpose-built packaging automation system, supporting the ‘soft’ integration deliverable. Schneider also delivers the practical advantages of a single source for the complete electrical solution, from safety to sensors to VFDs and I/O.

About Switchback Group

Switchback Group offers some of the most innovative and flexible End Load Cartoners and Case Packing equipment on the market. End Load machinery includes Automatic, Semi-Automatic, Intermittent Motion, Sleever and Hand Load style Cartoners. Wraparound, End Load and Robotic Top Load Case Packers are offered for packaging product into corrugated cases. Whatever the application in chipboard and corrugated, Switchback Group will offer a solution.

www.switchbackgroup.com

About ELAU packaging solutions

ELAU, Schneider Electric’s packaging specialist, equips over $1 billion worth of packaging machines annually. Currently, over 40,000 purpose-built ELAU packaging automation systems are deployed in machinery worldwide.

Through ELAU, Schneider Electric is the only controls supplier with a dedicated business unit focused exclusively on the automation of packaging machinery.

The market demands packaging operations that are more flexible, efficient and sustainable to fulfill marketing, supply chain and global business strategies. ELAU innovations have enabled a revolution in mechanical, software and hardware modularity to deliver these agile packaging systems.

For more information, visit www.elau.com or email [email protected].

Companies in this article