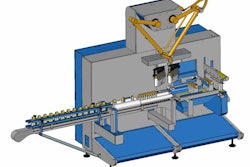

What are the options when you have longer packaging runs and run multiple shifts that need a robust coding ink supply? One answer is a bulk ink delivery system such as the RSI Print Systems’ Industrial Manifold System (IMS).

The reliable state-of-the-art system is built around a 350-milliliter ink supply that extends running time compared to the standard 42-milliliter ink capacity of

HP thermal inkjet cartridges. The bigger supply can offer cost advantages with reduced per-imprint costs and less operator attention in monitoring systems.

The bulk supply system uses a sturdy molded plastic cartridge to hold 350 milliliters of ink. It fits into an ink supply stall assembly that permits snap-in snap-out installation of the cartridge. The changeover is so fast that cartridges can be “hot swapped”—changed on the line by an operator while the line is in operation.

The IMS is engineered by RSI and jointly developed with HP. It uses modular components that permit it to be tailored to specific lines and specific needs. Key components of the system include the cartridges and cartridge stalls. It also includes the enclosed regulator assembly that allows the ink supply and the regulator itself to be mounted some distance from the packaging line. That way engineers can fit the application to a specific location and orientation of print heads.

The IMS utilizes quick-to-attach leak-proof connectors. They create a clean ink delivery system that is reliable and helps reduce the overall cost of printing. Electronic connection and components in the system allow integration into plant production management systems.

The modular components allow a range of configurations. The simplest could be one ink supply cartridge feeding one regulator which in turn delivers a single color of ink to as many as four print heads. The system could be as complex as a four-stall setup that feeds different colors of ink to four different print heads.

“The easy snap-in 350 milliliter cartridges can be replaced while the

production line is in operation” notes Jim Constantine eastern regional manger

for RSI. “This is a distinct advantage over other replacement methods which could only be done while the printer was off.”

Individual 350-milliliter ink supplies can hold a variety of HP-developed inks. Dye-based ink often produces brighter superior colors and generally adheres well to glossy stocks. Pigmented inks offer better light-fastness and water-fastness.

However generalizations about inks provide only guidelines. RSI recommends testing inks on the specific substrate to be printed. Drying time contrast and durability are factors that change with different substrates.

Contact RSI Print Systems

1-866-PRINT-HP www.rsiprintsystems.com

See the story that goes with this sidebar: Reliability key to GE choice of inkjet coders from RSI