Knoxville, TN-based Jewelry Television® sells more gemstones than any other company worldwide. With jewelry and gemstone shipments exceeding 5.5 million orders per year, secure and accurate packaging is a top priority for the company.

In 2011, when significant business growth neared the effective operating limit of the company’s distribution center, JTV took advantage of the initiative to expand to a bigger facility and review its packaging operations to seek greater efficiency. A paramount goal during the transition to the new, 65,000-sq-ft distribution center was to implement an automated packaging system that would meet the company’s needs to better handle the high order volume that came with such success. By enlisting the help of Sealed Air and implementing the company’s PriorityPak® automated packaging system, JTV has increased its efficiency by an estimated 15%, while maintaining a superior level of reliability that has resulted in the successful and secure arrival of products to their customers’ doorstep.

A priority on packaging

JTV evolved in a relatively short time from a small enterprise known in the early 1990s as America’s Collectibles Network into one of the leading retailers of fine jewelry in the U.S. Broadcasting its first live show on Oct. 15, 1993, JTV initially offered items such as collectible coins, knives, quilts, and skincare products. After a decade of successful broadcast and online sales, the company made the decision to focus on offering fine jewelry, gemstones, and gemstone-related products at reasonable prices—becoming the first television-shopping network to make this commitment.

The importance of choosing the appropriate packaging system for JTV’s products is underscored by the company’s business model, which depends upon successful delivery of products directly to the customer. With purchases made via phone or Internet, typically by those watching the company’s television channel, there is limited face-to-face customer interaction. As a result, a significant portion of the customer experience rests on JTV’s ability to fulfill orders quickly, securely, and accurately from among the 45,000 SKUs housed at its Knoxville facility.

“It would be nearly impossible to overstate the importance to our company of a reliable packaging solutions partner,” says Chris West, vice president of Logistics, JTV. “We don’t have a brick-and-mortar presence, so every item we sell is shipped. Getting those items safely and securely from our warehouse to their final destinations in a timely manner is critical to the success of our company.”

With packaging serving such an important role in the JTV customer experience, the decision to implement a new packaging format with the opening of the larger distribution center involved a deliberate process. JTV project manager Shannon Meade examined a number of options, narrowing the decision to a small group of contenders he felt had the potential to serve the company’s needs.

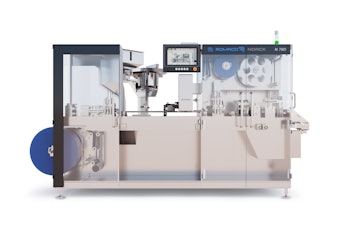

One was the Sealed Air PriorityPak packaging system, which offers a fully automated solution geared toward businesses that experience a fluctuation in volume and variation in packaging requirements—such as variably sized items. Combining high-speed product containment and protective packaging with advanced sensor technology, the system creates a complete, custom-sized containment package in one step. With the product transported via belt drive into the system, two rollers compress two layers of cohesive corrugated or laminate material around the item, suspending and protecting the item in the middle of the package. The Sealed Air Cold Seal® process seals the edges and locks items in place for a secure and tight fit. Products emerge centered, protected, and ready to ship in a custom-sized envelope.

To evaluate the considered packaging formats, a series of tests was completed prior to Meade’s final recommendation to the company’s management team to make the switch. The first test for the PriorityPak system was conducted in Sealed Air’s package design center in Ayer, MA. JTV provided a variety of products that the Sealed Air team packaged on a PriorityPak system. Products were then shipped from Massachusetts to JTV in Knoxville. Upon satisfactory review of the packages’ look and performance potential, the next step was to utilize the PriorityPak system for a trial run by packaging multiple shipments of product ordered by JTV customers.

With the tests completed and items processed, packaged, and securely delivered to customers, the decision was made to install five PriorityPak systems in JTV’s new facility in May 2011.

“We were looking for an automated packaging system that could increase package throughput and operational efficiencies, however the package also had to offer proven protection and ease of opening for a wide variety of customers,” says West. “The PriorityPak system does all of those things.”

A perfect fit

Since JTV installed its first PriorityPak system, Meade says he has seen Sealed Air provide continuous improvement and support. He considers PriorityPak to be one of the most compact and easy-to-use automated systems in the industry. “The equipment’s compact footprint is an ideal fit for our Tennessee distribution center, and the performance of both the system and the package has reinforced that we made the right decision to partner with Sealed Air,” he says.

The changeover to the PriorityPak system added an increased level of automation to JTV’s packaging operation, increasing efficiency and shortening cycle times significantly. Since implementing the system, the company has seen an increase of 15% in package throughput, without the use of overtime hours or increased labor, and has seen a full return on investment in less than 12 months.

Prior to the switch, the JTV packaging and shipping process was less efficient and more labor-intensive. Orders were picked by hand and sent to one of more than 60 individual shipping stations, each equipped with scales and multiple printers. Fulfillment depended on employees at shipping stations to scan tickets and place items on the scale manually, then print labels, place the product and invoice into a premade envelope, and apply the shipping label to the envelope. The process offered limited verification and required a great deal of space dedicated to picking, packaging, labeling, and shipping. In addition, JTV was restricted to just three premade envelope sizes to package all of its variably sized items.

With the current system, employees allocate incoming orders, picked via radio frequency device, to a tote divided into four sections, for up to four possible items. The tote is then placed onto a conveyor belt and scanned. Once the scan occurs, an invoice is printed and folded, then inserted into the appropriate quadrant of the tote. Based on which quadrant contains the invoice, the tote is routed to one of four lanes in the JTV shipping department. At that time, the invoice is scanned, and all items are verified to ensure the correct items are being shipped. An agent then transfers the items into a presentation box. Once these steps are complete, the agent places the totes on a line that routes to the PriorityPak system, where an operator removes the boxed item from the tote and places the item on the PriorityPak conveyor.

Upon entering the machine, the product is scanned with vertical and horizontal sensors that detect its leading and trailing edges, in order to create a custom-sized package with the product perfectly centered. Says Meade, “That’s one of the beauties of this system: The package is made to the exact size it needs to be, so you are not shipping a lot of air.”

The two layers of material used for the package—one for the bottom and one for the top—are both coated on the inside with a cohesive seal. With the Cold Seal cohesive seal, versus an adhesive seal, the layers adhere to one another after being pressed together, but do not adhere to the product. This locks and seals the product in place to minimize shifting inside the package. For JTV’s purposes, the bottom material layer is preprinted with JTV branding.

After the product is encapsulated in the package, the system automatically prints and applies the shipping label to the top of the package using a Zebra 110PAX4 printer, after which the item emerges from the PriorityPak securely packaged, weighed, labeled, and ready to ship.

The fourth lane at JTV is equipped with two PriorityPak machines to handle “fast-lane” items, as Meade explains. “By fast lane, it means the product doesn’t require special presentation, so it’s just a matter of performing a verification and then sending it down to the PriorityPak,” he says. “The product moves very quickly through our operation.”

Custom materials

Implementing the PriorityPak system enabled JTV to switch from cases of premade envelopes to rolls of material formed to a custom fit. For its PriorityPak envelopes, JTV is using proprietary packaging material with a custom-designed tear-strip opening on the top layer that is applied during production.

“The reason for the development of the tear strip was our demographic,” explains West. “We had an internal issue where we were having trouble opening the package with just the cold seal itself. We partnered with Sealed Air to put the tear strip in, and it has turned out very well.”

Traditionally, the PriorityPak can be used with three different choices of protective packaging materials: Priority Wrap® Bubble Laminate, PriorityWrap® Rigid Board, or PriorityWrap® Film/Paper Laminate.

Final test, the customer

JTV customers are known for being loyal but discerning, and they are highly vocal when it comes to the company’s products and services, particularly in the rare event their experiences leave them anything short of completely satisfied.

“The ultimate test for any change, be it packaging or otherwise, is what customers say after the change is implemented,” says West. “If customers were unsatisfied with the package, if items arrived in less than pristine condition, and if they thought the package was hard to open, we’d have known very quickly. The packaging has exceeded our expectations, and the compact equipment footprint and increased package throughput works well for our facility. It’s a big win all the way around.”