Designed for contract packagers or others requiring fast changeover and a wide size range, the new Veronica vertical semi-automatic cartoner from Ultra Packaging was designed from the ground up around servo technology. Instead of relying on mechanical line shafts and linkages, all the primary motions on the machine are servo-controlled and electronically synchronized, using servo technology from Bosch Rexroth’s Electric Drives and Controls Div.

The benefit is a 10 to 15-minute changeover, versus about 45 minutes on typical vertical semi-automatic cartoners, according to Ultra Packaging’s Bob Stockus. The small-footprint cartoner erects cartons, allows up to four people to hand-load product, and seals the cartons. The speed is 120 cartons/min in continuous mode at a 12” pitch, versus 60 to 80/min, which Stockus says is more typical for semi-automatic cartoners. The machine, which can also operate using intermittent motion, handles cartons from 2”Lx¾”Wx4”D to 10”Lx4”Wx12”D.

Because it relies on electronically synchronized servos, the machine is one of the first semi-automatic cartoners to completely do away with a roller chain, according to Stockus. Plant manager Rich Peterson elaborates: “We’ve basically taken away a lot of the mechanical content typically found on such cartoners, such as jackshafts, driveshafts, and sprockets,” Peterson says. “Now each primary motion is all done through a servomotor with a folding mechanism attached directly to the motor shaft.”

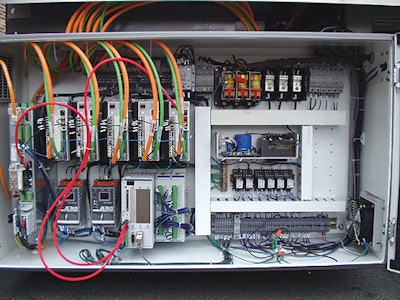

The machine uses six axes of motion, meaning it has six servo drives and motors. Bosch Rexroth Ecodrive C drives are synchronized via a SERCOS fiber-optic network. Instead of relying on a traditional PLC, the machine is controlled by Bosch Rexroth’s PPC Motion & Logic controller, which also controls the Nordson adhesive applicator.

In evaluating servo suppliers, Stockus cited Bosch’s track record in packaging, along with the multiaxis synchronization capability. Another important feature is that the servos do not require re-homing after a jam or emergency stop, which by design physically cuts off power to the motors. Upon restart, the system “remembers” where the motor shafts were positioned, speeding recovery from a jam or stoppage.