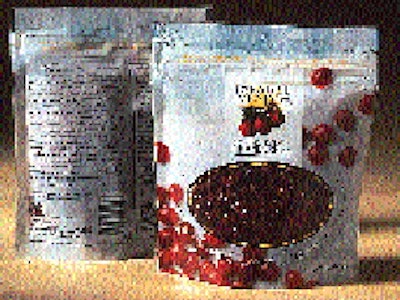

It started in 1994 with a prototype product packed in a cellophane bag. By 1996 it was a stand-up pouch, though only a mocked-up version, shown at the annual trade show sponsored by the Food Marketing Institute. Finally, in January of 1997, Decas Cranberry Sales' sweetened dried cranberries shed their R&D trappings and emerged on store shelves in a stand-up pouch proudly bearing the firm's Paradise Meadow premium brand name.

"Everyone loves the stand-up zippered pouch and we are very pleased with the way consumers are responding to the product from a quality standpoint," says vice president of operations Jeff Carlson. "We're also getting a very favorable reaction to the graphic presentation. We're confident that the product is going to be successful when it's introduced nationally."

Currently the 6-oz portions of dried cranberries, which sell for about $2.20, are only available in Michigan and portions of New England. That will change late this year when Decas, which is based in Wareham, MA, completes a new manufacturing plant in Carver, MA, the center of the famous Cape Cod cranberry region. With the completion of the new plant, output will be sufficient to support a national rollout.

From early on in this project, Carlson and colleagues knew that a premium quality image was essential. "We wanted a state-of-the-art package that lent itself to high-quality graphics," says Carlson. "It was important to separate our products from others in the market."

Decas gets the graphic impact it wanted in a film supplied by Curwood (Oshkosh, WI). It's a 48-ga polyester laminated to a 3-mil coextrusion of ethylene vinyl alcohol and linear low-density polyethylene. Curwood doesn't say whether the lamination is achieved by means of an adhesive or through extrusion. But the inclusion of the EVOH as a barrier layer helps keep oxygen from penetrating into the package.

This allows Decas to code the pouches with a one-year "best-if-purchased-by" date. The code is stamped on the film by a Markem (Keene, NH) unit shortly after the film unwind station on the horizontal form/fill/seal machine used for packaging. Ultimately the code winds up on the bottom gusset.

The polyester layer of the film structure is reverse-printed in seven colors on a gravure press. The upscale graphic concept features an intricate collage of historic Cape Cod scenes and images rendered in various shades of translucent white. To ensure top-notch reproduction of this detailed artwork, executed by Willis Advertising & Design (Hansen, MA), Decas specified gravure printing rather than the more conventional and less costly flexo process.

"Curwood's in-house graphics capability was invaluable in capturing the graphics on film and getting color, line, and image registration requirements just right," says Decas' marketing consultant, Tom Gorski. "With market interest in cranberries at an all-time high, with no sign of leveling off, we think it's vital to position Decas' Paradise Meadow brand as a quality leader. More specifically, we're hoping our new graphic image gives the Decas product more upscale, adult appeal."

The upscale look is an important differentiation since the main competition, Ocean Spray Cranberries, markets its dried cranberries in a zippered stand-up pouch using bright, colorful graphics for strong appeal to kids.

Also adding to the appeal of Decas' package is an oval window that shows off the fruit inside.

Customized copacking

The Decas stand-up pouch is about 6" wide, 2" deep at the base and about 6 1/2" high. It's produced from rollstock and given its zipper reclosure feature on-line by Roberts Packaging (Battle Creek, MI). The contract packager uses its own high-speed Roberts C-1000 horizontal form/fill/seal machine to produce the Decas pouches at 95/min.

Initially, feed rollers on the C-1000 draw the Curwood printed film through dancer rollers and a plow assembly that includes a "gusset tip" to fold the material up into a bottom gusset. Once the film is folded, an LDPE zipper profile from Presto Products (Appleton, WI) is heat-sealed in place.

"It has EVA [ethylene vinyl acetate] ribs extruded onto its flanges," says Roberts' Mike Boyd. "The EVA has a lower melt temperature so you can reduce dwell time and increase speed as you seal the strip to the rollstock."

Shortly after application of the zipper profile, heat-seal jaws close on the material to create the trailing side seal of one pouch and the leading side seal of the next. Then the pouch is cut from its web and gripped from opposite sides by clamps. Precise registration for side-sealing and cut-off is maintained by photocell sensors during these intermittent operations.

Hereafter, the pouches move continuously. To assist in the opening process, the clamps gripping them on both sides pivot inward. Also assisting are suction cups that pull the pouch open from front and back prior to nitrogen flushing. The nitrogen displaces oxygen before a seal is made, thus helping to prolong shelf life.

Combination scale

The cranberries, meanwhile, are being weighed by a 16-bucket combination scale from Heat & Control (Hayward, CA). Mounted above the Roberts system, this scale is divided so that half its weigh buckets dump down one chute and the other half down another into two large transfer chutes that reciprocate between the two positions. Chutes receive their charge of cranberries on the backstroke. As they stroke forward their bottoms open and they discharge the berries into two of 15 filler funnels that move constantly around the Roberts machine in a track shaped like a large oval or ellipse.

Charged filler funnels are mechanically lowered into a pair of pouches, and spreaders open each pouch before product is dropped in. As the pouches continue forward, the funnels and mechanical spreaders retract.

In the next station, the pouch clamps pivot outward to begin the closing process. Three sets of reciprocating heat-seal bars close and seal three consecutive pouches. The sealed pouch then is released to a discharge chute for manual case packing.

When Decas completes its new production facility in Carver, all of the Paradise Meadow sweetened dried cranberry products, including two line extensions now in development, will be produced there. But at this point it's unclear if packaging will be included. It all depends on demand once Decas initiates its national rollout.

Says Carlson, "With the unique Cape Cod cranberry, we have the premium quality product of the industry, plus a packaging concept that strongly positions the product on the shelf." It's a combination that could make Decas Cranberry a big winner.