When supermarkets began carrying ever larger multipacks of bathroom tissue a few years back, paper companies like Atlanta-based Georgia-Pacific were only too happy to oblige. But it took time to sort out the packaging implications of this trend.

For Georgia-Pacific, loading multipacks into corrugated shippers proved especially challenging. The obvious quick answer was to case pack by hand while seeking equipment that could do it automatically. Finding such equipment, however, proved more difficult than expected because G-Ps package configurations varied.

It was easy enough to handle eight-roll, 12-roll, and 24-roll film-wrapped packs because a variety of counts total 96 rolls in the exact same case. Twelve eight-roll packages take a 3 x 4 x 1 pattern, eight 12-roll packages take a 2 x 4 x 1 pattern, and four 24-roll packages are packed in a 2 x 2 x 2 pattern. Regardless of how these configurations are handled, each case receives an accumulated stack of rolls thats six across, four high, and four deep.

But one multipack also in demand at the supermarket is the nine-roll version, and since nine wont divide evenly into 96, this package needed its own case and some special handling.

The answer was a custom-built system from R.A. Pearson Co. (Spokane, WA), developed first for G-Ps Bellingham, WA, plant. Not only does it erect, load and seal cases, it also collates and downstacks bundles of rolls before delivering them to the loading station. Two systems are case packing rolls of bathroom tissue at Bellingham. A third is used for paper towels. The most recent of the three was installed last year, and all three are huge. Pearsons Jerry McBride explains why.

The issue is speed, says McBride. In order to accomplish the rates requested, we had to move rather large blocks of material. That in turn dictated the size of the machine. Pearson may have made other types of equipment bigger than this one, but this is the largest case packer I can think of that weve built.

Most production runs at Bellingham involve nine-, 12-, and 24-roll packs. The Pearson equipment handles nine-roll packs at eight cases/min, 12- and 24-roll packs at 5.6 cases/min.

Large cases

Naturally, the cases are large as well. Supplied by Georgia-Pacifics (Atlanta, GA) own corrugated division and made of 23-lb ECT C-flute corrugated, they measure 23.38 long x 15.5 wide x 18.5 deep. For the nine-roll packs, the case length is the same at 23.38, but width is only 13 and depth 14. This case is also loaded differently. With the 96-roll cases, the multipacks lie flat and are stacked on top of each other as theyre loaded into the case. When the nine-roll packs are inserted, however, they are pivoted 90 so that a stack five-high becomes five vertical packs. The Pearson equipments ability to do this is what makes it so special, says Don Buchanan, the now-retired G-P engineer who oversaw the case packers development.

The other manufacturers dont have a machine that can load in two different orientations, says Buchanan. Neither did Pearsonuntil they developed one to solve G-Ps problem.

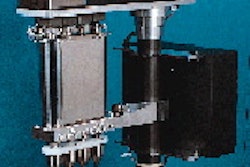

The device that reorients the accumulated multipacks is best understood by looking at Figures 1 and 2. In Figure 1, the accumulated flat stack of packs is transferred into the loading station and then pushed into the waiting case while still horizontal. In Figure 2, accumulation and transfer to the loading station is the same. But before product is pushed into the case, a rotating bucket pivots 90 so that the packs are oriented vertically. This bucket is used only when the nine-roll multipacks are being packed, but it doesnt have to be removed when other configurations are in production. It has removable pins that allow it to drop down safely out of the way.

Frequency of changeover from one multipack to another is based on customer orders. It takes only a few minutes to change the case packer when changing between eight-, 12- or 24-count packages. But in going to the nine-roll multipack, changeover takes a little longer because the case handling mechanisms and the rotary bucket must be adjusted in addition to the various sweeps and guide rails that are a part of all changeovers. Regardless of which multipack is being loaded, paddle-like devices slide into the case opening to serve almost as funnels. Thus, as product is pushed into the case, the paddles keep the flaps out of the way.

Laning comes first

Figure 3 shows the rest of the systems operation. First the infeed conveyor divides the flow of multipacks into two or three lanes, depending on which count is being handled. Accumulation and downstacking produce the proper stack height. The stacked product indexes forward into the loading station or the rotating bucket. All that remains is a push into the case.

Meanwhile, cases are picked from a vertical hopper by vacuum cups that reach up and bring individual flat blanks down into a flighted chain conveyor. In the first station, the flat blank is opened, again by vacuum cups that attach from both above and below.

Next the case indexes into the loading area. Minor flaps opposite the loading side are closed and the product is inserted. In the next station, a Nordson (Duluth, GA) unit applies glue to the minor flaps on top and bottom and the major flaps are plowed closed. Finally, glued flaps are compressed. The finished case is then tipped from its side onto its bottom and discharged to remote palletizing.

Feeding of the knocked-down corrugated blanks is accomplished with help from a scissor lift. When one stack of blanks is nearly empty, the operator presses a button to bring the scissor lift down. Then a fresh stack of blanks, queued up with other stacks on a roller conveyor, is pushed onto the scissor lift. The lift continues to rise as blanks are needed, returning back to floor level for a new stack when necessary.

From the top of the stack thats on the scissor lift, individual blanks are pulled by suction cups and dropped one at a time into the vertical hopper. About a 1-thick stack is kept in the hopper at all times. Its kept from getting overfilled by a high-level sensor that stops infeed of blanks if blocked.

One operator is required to run the Pearson system; manual case packing had been done by two or three people. Naturally, the savings in labor costs is appreciated. But Buchanan is equally impressed with how forgiving the equipment is.

Its not like doing boxes of Cheerios or bottles of Pepsi, he observes. Our product varies in density and diameter, sometimes even from package to package. The case packer had to be prepared for all these variations.

G-P was so pleased by the advantages the Pearson equipment brought to case packing of tissue, management also had a similar system built for the Bellingham plants line of paper towels. Again, the rotating bucket in the loading station is the key.

The first Pearson installed, recalls Buchanan, being a prototype, required a pretty lengthy learning process, not only in getting our folks used to it but in mastering the changeovers from 12-roll to nine-roll packs. But Pearson provided people and expertise to help us through it. Anything that went wrong, they had people here in the middle of the night. Once we got over the development issues, the machines really ran. This last one installed is a great machine.