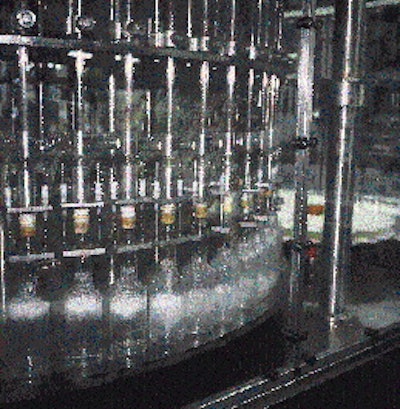

The line accounts for 500ꯠ cases a year, filling products in seven different bottle shapes. The machine, from MRM Elgin (Menomonie, WI), runs at 145 bottles/min, though vice president/operations manager David Hobbs plans to boost that to about 180/min when a third P.E./Executive labeler from B & J is added this month. The new filler is rated at 300/min speeds, though downstream equipment prevents attaining that rate at this time. No matter which of these speeds Heaven Hill operates at, it will certainly improve on the 30-valve rotary filler that it replaces. The new filler, says Hobbs, "has reduced downtime and associated maintenance costs by roughly 20 percent." In operation, bottles are uncased, rinsed and conveyed to an infeed screw that delivers bottles single-file into a starwheel. Bottles, provided by Anchor Glass Container (Tampa, FL), index into the machine. Each bottle is positioned underneath a fill nozzle. The product is gravity-fed from a 100-gal hopper/tank, through a manifold, then through a stainless steel fill tube for each of the 60 nozzles. A spring device compresses the product fill port of the nozzle to allow liquid to flow from the fill tube past an overflow port, sealing washers that contact the top of the bottle, then into the end of the nozzle. With the nozzle's flow hole in the open position, liquid flows continuously. When the liquid reaches a product level area just above the flow hole, the excess is drawn from the valve out of the filling tube, yet still within the nozzle. This overflow is drawn by vacuum up through the overflow port and recirculated through the system. A central manifold cuts off product flow immediately prior to the nozzle lifting out of the bottle. "The process is accurate to within 0.03 mL," notes Edward Kirsch, maintenance supervisor. "The federal government regulates the liquor industry tightly, and we are careful not to provide less than the amount indicated on the bottle. On the other hand, we have to be careful not to add too much alcohol or else we'll lose money. The filler represents quite a step up from the antiquated machine it replaced on this line," Kirsch concludes.