This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

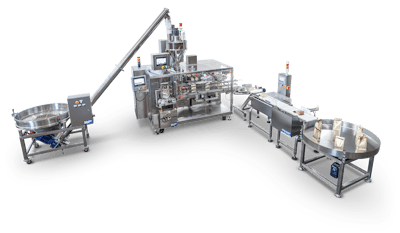

Engineered for a client packaging ground coffee, and built specifically for the client’s existing bag sizes, this automated system conveys ground coffee from a hopper up to the Star Auger powder weigher via a screw conveyor. Once weighed, it passes into WeighPack’s Swifty bagger box gusset bagging machine where it is dispensed into premade bags before the sides are tucked and the top is sealed. Bags are then conveyed to the WeightCheQ check weigher to ensure each bag meets the preset weight tolerance before it is accumulated on a rotary table.

Unique system features include an integrated bag shaker to fully settle the product in the bag prior to sealing, and a product rejection system to prevent the accumulation of bags that are outside of the desired weight tolerance. The system was designed to easily allow future integration of case erecting, case packing and palletizing solutions.

“We designed this integrated coffee packaging system to weigh fill up to 1500 bags per hour to meet the needs of the most progressive coffee retailers. And our larger wholesale clients can expect to fill up to 600 of their larger bags per hour. By combining our new box gusset bagger with our auger coffee filler and downstream check weigher, our clients get a turnkey system that’s easy to integrate so they can ramp up production immediately,” said Nick Taraborelli, Vice President at Paxiom Group. “We also designed it to work with our other vibratory weigh fillers for our clients packaging whole bean coffee.”