This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

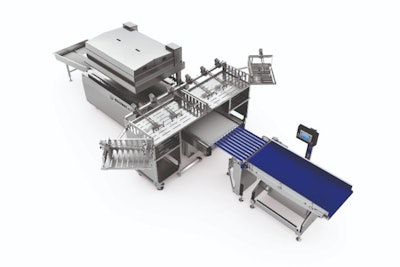

When packaging products on belted chamber equipment, the filling of the film pouches and the loading of the machines are often a bottleneck in the process. This work is usually carried out manually and requires labor-intensive product handling. To ensure full capacity utilization it typically has required five people on the production line: three for filling the film pouches with product and two for loading the chamber belt machine.

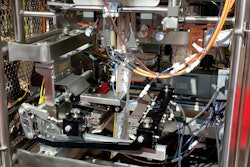

By using the new Multivac pouch loader and pouch rack, the loading of the chamber belt machine is performed semi-automatically, enabling an average of 40% cost reduction in labor required to load product. Based on a daily typical fresh meat plant output with a belted chamber machine, it can also eliminate the need for employees to physically lift up to 10 tons of product, when compared to the manual loading process. This solution enables significant increases in efficiency and ergonomics while providing cost reductions.