If you want to cut time out of your package development process, you may want to consider the recent example at Ecolab, St. Paul, MN

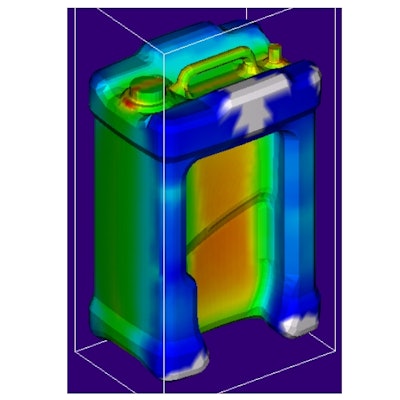

During the development of Ecolab's complex, award-winning ProForce package, Stress Engineering Services (www.stress.com) conducted state-of-the-art stress engineering modeling to help design the 1.25-gal HDPE bottle and mold. Containing a ready-to-use cleaning solution, the large bottle features a "pocket" or indent where a separate16-oz refillable bottle of the solution is nested.

SES's design studies and computer modeling and simulations were performed to predict problematic areas and adjustments to the package were made accordingly. A particularly effective feature is the load-locking nubs at the top of each container that fit into corresponding indents on the package positioned above it. The design helps stabilize the load and contribute to a case-free pallet.

Bridge addressed

Ecolab's director of global supply quality Tina Outlaw says the “bridge”—located above the pocket where smaller bottle is nested—was a key area of concern. Because of the lack of corrugated in any of the packaging, the bridge would have to take the brunt of top-to-bottom compression when the containers are stacked.

“We made sure that when we designed the [mold tooling] in three sections so that portion of the tool could be modified if we needed to do some tweaking," Outlaw explains. "Using SES's failure-mode analysis, we could anticipate problems and determine what kind of polymers were most suitable." Those studies led them to use high-impact HDPE.

Outlaw estimates that the use of computer modeling cut eight months out of the package development timeline.

Ecolab has used SES on projects over the past 25 years, but Outlaw says those were more in reactive mode for problem solving, rather than a proactive mode as this project was.