With operations in 58 countries and consumer brands in 180 nations, it’s a good bet that Chicago-based Sara Lee Corp. knows a thing or two about packaging. That’s evident at its Paris, TX, plant, where the Sara Lee Bakery Group facility operates a prototype system that automatically feeds, sorts, and wraps six “mini donuts” in film.

Installed in June ’01, the mini-donut system was co-developed by Sara Lee and supplier Delta Systems (Rogers, AR). The system differs from some other wrappers in that it uses a continuous-motion rotary drum loader that accepts donuts from a vibratory infeed conveyor, rotates, and deposits them onto a discharge or lug conveyor for downstream wrapping.

“Before adding the system, employees hand-fed, counted, and sorted the donuts,” recalls Paris plant manager David Owens. “The Delta machine replaced a completely hand-fed machine.” He says, “We wanted to make the process more efficient and effective.” Although Owens says those goals have been achieved, he would not quantify efficiency improvements or labor savings resulting from the more automated wrapping process, because the labor issue was too sensitive. According to Delta, the system requires only two operators: one at the wrapping section, another upstream near the vibratory conveyor.

Sara Lee Bakery’s decision to use a wrapper from Delta began, Owens recalls, “when we first saw a Delta wrapper at a Pack Expo Las Vegas show.” That, he believes, was in 1999. “We began talking with Delta about a concept of how to package these donuts, and they were interested. We worked together to build a prototype unit.”

According to Delta, the machine was approved during a three-day testing period where it produced upward of 100 packs/min, operating at 98% efficiency. That’s the speed the machine was designed to operate at in the Paris plant.

“Production is presently running at a rate of efficiency that’s generally in the mid-nineties,” asserts Owens. He points out the system runs two 10-hour shifts per day, five days per week. Sara Lee packs mini donuts in chocolate, powdered sugar, and cinnamon varieties.

Examining the process

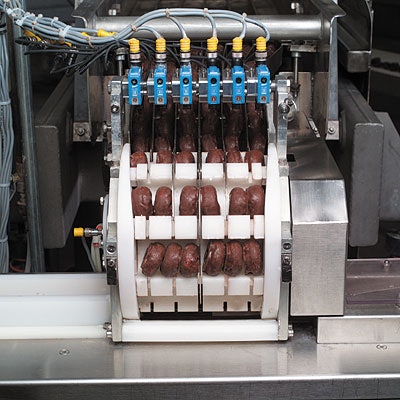

At the 335ꯠ-sq’ Paris plant, donuts are delivered from processing areas on a belt conveyor into the first section of the Delta vibratory conveyor. All food-contact surfaces on the Delta equipment are stainless steel, with the system designed to accommodate washdowns. Product is conveyed into a second section where donuts continue through stainless-steel dividers that separate donuts into six lanes. Just downstream, the conveyor narrows in width, forcing donuts in each of the six lanes to shift from horizontal to vertical.

Photoeyes sense six donuts as they move into slots positioned across the rotary drum. The drum contains eight of these six-wide slots or cavities. As the drum indexes, donuts are held in these cavities. Much of the drum is shrouded with a stainless-steel cover to prevent donuts from falling out of their cavities. When the six donuts index around the drum they are deposited onto a paperboard “card” positioned between leading and trailing lugs on the conveyor that moves in an oval-shaped track pattern. The unprinted cards are produced just upstream of the drum by a rollstock feeder that cuts and places them into positions on the lug conveyor. As they’re held between the leading and trailing lugs, the six donuts are conveyed about 7’ downstream to the forming section where the donuts are conveyed into a tube of film. Side pin lugs in the fin-seal area and the conveyor’s side rails help hold donuts in place as the leading and trailing lugs retract.

Wrapping begins as a servo-driven film feed delivers the 0.8-mil coextruded polypropylene film, flexo-printed in four colors by Cello-Wrap Printing (Farmersville, TX). A Markem (Keene, NH) coder applies a date code to the film as it unwinds. The film continues around the forming box, creating a film tube into which the donuts are conveyed. A fin seal is made along the bottom of the package while a heat seal is made across the leading edge of the film. A seal across the trailing edge simultaneously creates the leading seal of the next package. A knife cuts between the seal area, and the leading package discharges onto a takeaway conveyor that carries wrapped packages to secondary packaging operations.

The mini-donut system uses SoftFlow PC-based motion-control software that integrates servo motion throughout, including the lugs, film feeding, sealing, and cut-off. Photoeyes and proximity sensors are also included, sensing product, card and film positioning, as well as detecting proper positioning of the rotating drum, card feeder and cutoff, lugs, film cut-off, and other vital machine components. A human-machine interface allows operator access.

More machines likely

Currently, the Paris plant uses the Delta system only for six-packs, though the equipment can be designed to handle four-, six-, and eight-count packs.

“Sara Lee has produced these mini donuts for many years, at different plants,” Owens explains. “There is no difference in speed of this machine versus the other, there’s just a lot fewer people feeding donuts into it. The service from Delta has been really good. They’ve provided us with training, and we’re going to have additional training in the future on it.”

Owens says “this is the only machine like this in the world. It’s a prototype. We intend to get more of them,” he says, adding that the equipment would likely be used both at Paris and at other Sara Lee bakeries around the country.