A robotic workcell from Automated Assemblies Corp. (AAC) started up in May 2004 at Mar-Lee Companies, Fitchburg, MA, injects additional capacity and efficiency into the company’s operations. Using two robots, the workcell provides automated in-mold labeling (IML) for injection-molded hinged lids used for containers of baby wipes.

The workcell operates 24/7 in conjunction with a new high-speed injection-molding machine, applying the labels before it loads the decorated IML lids into corrugated containers.

“The workcell started up without a hitch, it runs great, and everyone’s happy,” says Stan Bowker, director of molding operations. “This was a nice joint effort with AAC to get automation right where we needed it. AAC was responsive and very engineering savvy.”

The 5”x3” hinged lids are molded of polypropylene resin provided by at least three suppliers, says Bowker. Lid pigments include white and other colors, depending on the private label brand being produced.

AAC’s Raptor Model SE-310 side-entry robot picks and places the labels using suction cup-equipped tooling eight-up into the mold cavities with an accuracy of 0.02’’. The instant after the labeled part is molded, the part is removed by the robot. This makes for speedy production: Bowker says the workcell reduces their cycle time by two seconds, which is 25% faster than its two other IML workcells. The latest workcell adds an output of 20 million decorated lids per year to augment Mar-Lee’s other workcells. The workcell produces a number of versions of the part for one customer’s numerous private-label clients.

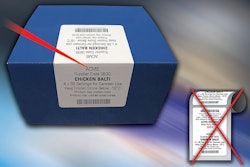

The decorated lids receive a 100% visual inspection check by an In-Sight® Model 4001 high-resolution (1024x768 pixels) machine-vision sensor from Cognex using the vendor’s PC-based In-Sight Explorer software. It checks for label presence and position on eight lids simultaneously as they are held by the robot. To inspect the position of the label on the lid, Bowker says it checks a centering tolerance within 0.04”. Mar-Lee liked the automated vision inspection so much that it plans to retrofit its two other older workcells. The decorated lids are transferred to a six-axis robot that packs a corrugated case with 720 lids, eight at a time.

IML impresses

Over the last three years, Mar-Lee has become a major proponent of IML versus print-and-apply labeling. “Instead of running the lids to a separate labeling operation, they are molded right into the lid,” Bowker points out. “It eliminates peeling or having labels bubble or blister.” The PP-based, 3-mil labels are supplied by Renaissance Mark.

“Because we mold to order, there are no finished lids awaiting label application, so our arrangement eliminates work in process,” Bowker adds.

Mar-Lee’s customer was drawn by the benefits of IML, according to Bowker. “It switched to IML from p-s labeling and gained market share, because IML yields a better package,” he says.

Mar-Lee has since become the company’s sole supplier of the IML lids, according to Bowker. In fact, Mar-Lee’s customer has become the top private-label supplier of wet wipes in the world, he adds.