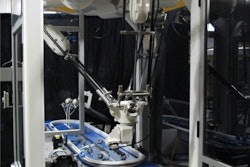

ESS Technologies Inc. has redesigned its Robotic Mini Pallet Cell to incorporate Fanuc’s new compact robot controller, the Model R-30iB “A-cabinet,” in place of the larger, standalone “B-cabinet.” The front panel of the stackable controller A-cabinet fits flush with the Category 4 interlocked and gasketed safety guarding system to create a streamlined robotic cell that does not require additional floor space for the robot controller.

Previous ESS pallet cell layouts incorporated the B-cabinet robot controller, which could not be stacked or installed flush with the guarding due to its size and shape. By replacing the controller with the powerful A-Cabinet, ESS engineers reduced the overall size of the pallet cell while increasing functionality and user-friendliness. ESS integrates a Fanuc multi-axis robot with its in-house, custom-designed, end-of-arm robotic tooling (EOAT), which offers a fast changeover time (5 min or less), and programs the cell to handle the required pack pattern.

The upgraded R-30iB A-cabinet controller also features a redesigned, lightweight 4D graphic iPendant for ease of use. The energy-saving controller design minimizes power consumption for the robotic cell. The controller comes equipped with fully integrated iRVision hardware for easy error proofing, and 2D and 3D robot guidance.

The complete palletizing system includes a case infeed conveyor, Category 4 interlocked and gasketed polycarbonate safety guarding, robot tooling, and programming for one case size. ESS can design the EOAT to pick one case or multiple cases at a time. The EOAT can also be customized to handle other processes, such as pallet placement, deck sheet/tier sheet placement, and case inspection with reject. The Robotic Mini Pallet Cell is available in single and dual-pallet configurations and can palletize 20−25 cases/min.