This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Hai Robotics, a distributor in warehouse automation, announced the release of HaiPick Climb, a robotic solution that simplifies goods-to-person automation, enabling warehouses and distribution centers to retrofit existing facilities. It increases throughput while reducing implementation time and costs compared to traditional Automated Storage and Retrieval Systems (ASRS), making ASRS more accessible and affordable for a wider range of facilities.

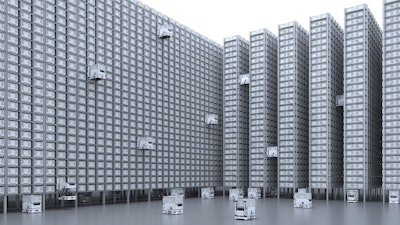

The HaiClimber robot, a compact climbing robot, offers a simplified way for warehouses and distribution centers to boost efficiency, increase storage density, and scale operations — with minimal infrastructure requirements.

“We know that many warehouses want to automate but are put off by the complexity and cost,” said Richie Chen, Founder and CEO of Hai Robotics. “That’s why we created HaiPick Climb — to deliver powerful automation without the need for major facility modifications. Our system is built on simplicity, requiring only standard racking and minimal floor preparation while providing top-tier performance.”

A Simpler Way to Automate

The HaiPick Climb system is designed for easy installation, operation, and ownership, with expansion and system modifications — while advancing the benefits of traditional ASRS.

Hai Robotics' goods-to-person solutions are recognized for their ability to automate storage and retrieval for a range of tailored needs. HaiPick Climb now offers a standardized solution that makes automation accessible to more facilities.

Easy to Implement and Scale

HaiPick Climb operates by attaching climbing channels to one side of most industry-standard racking. Compact robots travel up and down these channels, retrieving totes from both sides of narrow aisles. Since the system mounts from one side, it requires less infrastructure and is more tolerant of floor irregularities than typical ASRS, reducing facility preparation and cutting implementation costs.

The system is easily expandable with minimal disruption, enabling phased implementations and modifications without interrupting operations.

Easy to Operate and Maintain

Human travel for order picking is eliminated with the HaiPick Climb system. Totes of goods are automatically delivered to one or more ergonomic workstations that are easy to use and quick to learn. A simple interface makes picking fast and efficient with a 99%+ accuracy rate.

The HaiClimber robots are easy to maneuver and maintain. Their mechanics are easy to access, with half the climbing mechanisms of typical climbing robots, simplifying maintenance. Aisles allow just enough space for standard compact scissor lift access, eliminating the need for specialized equipment to access the system’s interior, while the use of industry-standard racking makes maintenance simple.

Throughput Efficiency

HaiClimbers navigate under racking, allowing for direct and optimized paths for each tote delivery and avoiding robot congestion that can occur in aisle "highways." Robots have direct access to every tote at all times, eliminating the wasted response time associated with searching or digging.

Traveling an extreme speed of 4 meters per second (13 feet per second) and climbing at 1 meter per second (3 feet per second), the HaiPick Climb system can process 4,000 totes per hour within a 1,000-square-meter (10,764-square-foot) space. Totes are delivered to workstations in as little as 2 minutes after order receipt — 34% faster than traditional ASRS — allowing for extended order cutoff times for same-day fulfillment.

Maximum Storage Density

Facilities can achieve 30,000 storage locations within a 1,000-square-meter (10,764-square-foot) space, with totes stored up to 12 meters (39+ feet) high. This is over 6 times higher than manual storage operations and provides 35% more vertical storage capacity than other leading ASRS solutions.

Narrow aisle widths, minimized to 900 millimeters (35.5 inches), further optimize space utilization. This combination of high storage density and vertical access enables facilities to reduce their storage footprint by up to 75%.

“This isn’t just automation — it’s empowerment,” Chen said. “HaiPick Climb allows businesses to achieve new levels of efficiency and scalability without the typical barriers of ASRS. It’s about making advanced automation available to everyone.”