This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

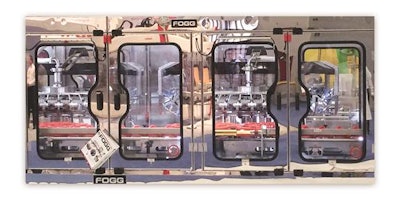

Stainless steel door frames offer a fresh new look, while still allowing visibility of rinsing activity from the outside. The stainless steel frame supports all hardware and hinges, eliminating thermal expansion, and allowing for tighter tolerances and better fume containment. This new door style enables chemical fumes from the rinsing machine to be better contained inside the enclosure, and then evacuated outside the building through an exhaust system, or chemical scrubber.

Now, enclosure doors are completely removable with quick and easy “lift-off” hinges. Simply flip up the cable guard, which runs across the top of the enclosure door, and unplug sensor wiring. Once the wire is free, the door can be lifted up and off its hinge for easier maintenance and changeovers. The spring loaded cable guard and simple lift-off hinges make this process tool-free and faster than ever. Safety switches on enclosure doors are best in class and Fogg also offers logo etching on enclosure doors for a more personalized machine.