This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

New updates include:

• A simplified loader design with multiple outfeed and loading options to fit into a production environment, including flat drop and tail drop

• Improved safety features such as additional protective guarding and interlock safety switches with an area scanner

• A simplified operator interface (HMI screen) with a pre-programmed, recipe-driven menu for quick and easy changeover of bag sizes, product, volume and more

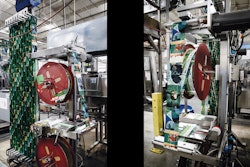

The Liquibox Orbiter is ideal for high-volume processors across a wide-range of products: dairy, water, post-mix syrup, edible oil, motor oil, and more. It can fill up to 7,500 gal/hr (30,000 liters), making it three times faster than other systems on the market. And, its highly customizable design handles multiple bag and fitment sizes, with fresh and extended-shelf-life options.