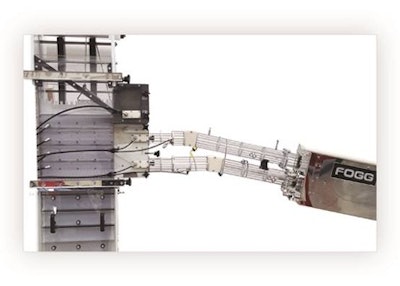

Dual cap chute

Design eliminates the need to climb onto a mezzanine or platform to change the cap chute on the cap sorter, as well as the risk of possible damage to the chutes during changeover and storage. Fogg’s dual cap chute design handles a variety of closure combinations and sizes ranging from 18 mm to 60 mm.The dual chutes travel from the cap sorter, merging into one single location to feed into the j-chutes of the capper.

Companies in this product