Manual loading of spiral-wound cartridges into a four-lane volumetric filler was too slow and carried the risk of repetitive-motion injuries. So the Liquid Nails Div. of Akzo Nobel LLC looked for an automated cartridge unscrambling and infeed system for its Liquid Nails line in Temple, TX. Their search led to a custom-built system called the Necosort-85-TS from Nalbach (www.nalbach.com) that was installed in November of 2007.

“The sorting bowl is fundamentally the same as many of the systems that Nalbach makes,” says Todd Baker, project and reliability engineer at the Temple facility. “But the star wheel infeed portion of the system is pretty special in terms of meeting our specific needs.”

The cartridges, which hold 10 oz of the very viscous Liquid Nails construction adhesive, begin the filling process when they’re dumped by hand from a large corrugated shipper into a floor-level hopper. A flighted incline conveyor carries the cartridges to an overhead sorting bowl that sits at a 30-degree angle. Cartridges fall to the bottom, or 6 o’clock, position of the large bowl and settle into one of the many pockets that move continuously around the circumference of the bowl in a clockwise direction. At this point, cartridge dispensing nozzles are randomly oriented.

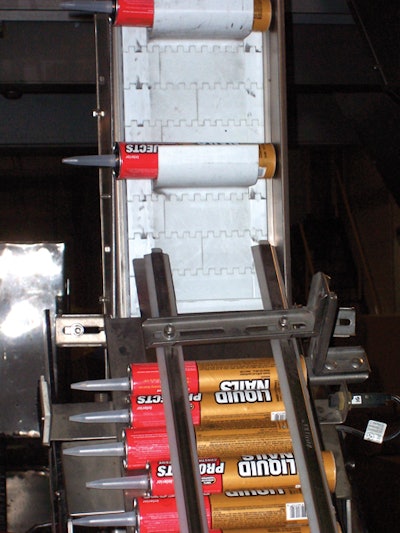

When cartridges in their pockets reach the 12 o’clock position of the bowl, the design of the tooling causes them to be suspended by their nozzles with the body hanging directly below. The cartridges then drop down a chute, nozzle trailing, and make their way to a flighted takeaway conveyor and then to a chute that feeds them into a starwheel feeding system. Cartridges are advanced by the starwheel into a position from which they can be pushed at a right angle, four across, into the pockets that carry them through the volumetric filler. It’s this section, from the takeaway conveyor to the cartridge pusher, that Nalbach custom-designed for Akso Nobel Paints.