This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Weber Marking Systems has announced the introduction of its new Model 5100 Dual-Label pallet printer-applicator, which marries a high-performance label print engine with a specially-engineered articulating applicator to perform the printing and adjacent-side labeling of pallets in line.

Designed and manufactured by Weber, the Dual-Label system features a selection of 203- or 300-dpi print engines to handle labels up to 6.5 inches wide and 8 inches long. Systems print labels with text, bar codes and graphic images at print speeds up to 12 ips.

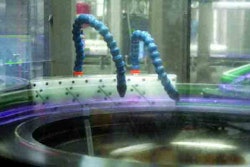

As a label is printed, it is automatically peeled from its liner and retained by vacuum on the unit’s applicator pad, which is mounted on a pneumatically-operated swing-arm that reaches across the leading side of a pallet as it approaches the Dual-Label system via conveyor. A sensor on the swing-arm detects the presence of the pallet and the label is gently blown onto its side.

The swing-arm then retracts to collect a second printed label, which is followed by an articulated stroke that applies that label to the adjacent side of the pallet to complete the cycle. The system can print and apply labels to up to five pallets per minute.

The Model 5100 Dual-Label pallet printer-applicator operates with Weber’s Legitronic® software, which simplifies label formatting, editing and printing. Weber also manufactures a wide variety of blank and custom-imprinted, pressure-sensitive label materials.

Companies in this product

Videos from Weber Packaging Solutions