This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The Beltweigh/MM is powered by high-performance servo motors that minimize vibration and improve weighing accuracy. It includes DSP, Hi-Speed's patented advanced noise-filtering system, which further enhances accuracy, especially in high-throughput applications. Its solid, heavy-duty construction provides a rugged, stable foundation for precise, consistent checkweighing and is well suited for operation 24 hours a day, 7 days a week.

The operator interface consists of a membrane keypad and LCD, which facilitate easy product set-up. A large character display is dedicated for weights. The Beltweigh/MM has password-protected programming for up to 25 products. Programmed speeds are stored with individual product setups for fast and easy product changeover. The Beltweigh/MM allows for both PLC and PC connectivity. Hi-Speed Cornerstone checkweighers are backed by the most comprehensive warranty in the industry.

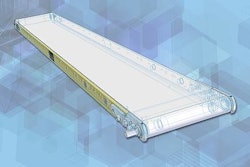

The Beltweigh/MM is a three-conveyor checkweigher that is designed to weigh, classify, and reject uniformly timed packages in a single mainframe. The system consists of an infeed conveyor, a weigh conveyor, and a discharge conveyor with machine-mounted reject device. The infeed conveyor is designed to accelerate products to provide the proper spacing for weighing. The weigh conveyor weighs and classifies the product into a customer-defined weight zone and transfers the product to the discharge conveyor. A machine-mounted reject device located at the discharge conveyor will remove off-weight packages, allowing only acceptable-weight packages to continue downstream.

All of the conveyors are standard with variable speed operation, allowing a wide range of package sizes to be accomodated on the same system.