Lucent Technologies believes it's at the center of a "communications networking revolution" that will see the global market for networking communications products total $650 billion by 2001. But "evolutionary," not revolutionary, would best describe the approach to packaging at the Denport West facility of Lucent's Business Communications Systems Group. At the end of last year, this Denver facility "evolved" to molded pulp cushioning from expanded polystyrene cushions. The change:

* Reduces warehouse handling

* Reduces labor costs

* Speeds manual packing

* Eliminates the need for electrostatic discharge bags

* Provides better product protection

* Frees warehouse space

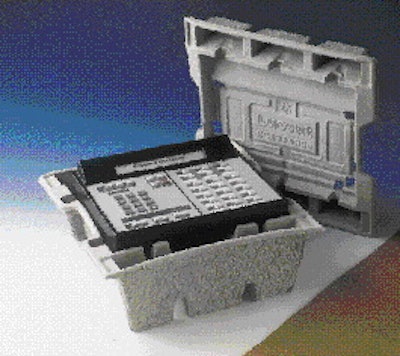

The molded pulp cushions are used to safeguard shipments of business telephone equipment. Product is shipped directly to business customers, to Lucent facilities or to third-party businesses. The cushions are referred to as "multifunctional packaging inserts" by Joan Bagwell and Roger Merriman. They're co-designers of Lucent's custom-molded inserts, which are manufactured by Eco-form (Walpole, MA). Lucent purchases them through distributor Hisco (Houston, TX). The project was coordinated through International Technology Packaging (London, Ontario, Canada).

Assembling benefits

Molded pulp is "multifunctional" in that these inserts are used throughout Lucent's phone-assembly operation, from receiving to distribution of finished goods. The previous EPS cushioning only functioned during shipping, where they provided protection.

The Denver plant receives the custom-molded pulp inserts from Complex Tooling and Molding (Boulder, CO), the company that injection-molds the plastic upper and lower housing pieces that become part of Lucent's telephone equipment. Complex Tooling and Molding stacks the upper product housings and upper molded pulp inserts separately from lower housings and lower molded pulp inserts. It then places them onto pallets and stretch wraps them. Lucent's trucks pick up pallets from the nearby supplier.

"When we were using EPS cushions, we received them separately from the top and bottom plastic housings that make up the shell for our phone terminals," recalls Merriman, a member of Lucent's technical staff. "The cushions came in plastic sleeves, and we had to stack them in our warehouse. Physically they took up a lot of space.

"Now we no longer have to bring in packaging material separately at our facility and store it. Instead, it comes along with the housings and moves along a conveyor with the product throughout assembly. The change has given us between a 5- and 10-percent savings in floor space."

The assembly process also is less labor-intensive. In the past, the top and bottom housings were received at the Denver facility in a protective polyethylene bag that was coated to help prevent electrostatic discharge (ESD) problems. "When we received these, we had to open the case, take the housings out of the bag, assemble the product, add the top and bottom housing pieces, put that assembly back into the bag, add the EPS cushions and put [the entire configuration] into a box for shipping."

Now the molded pulp serves as a holding fixture and tray. The process involves assembling the phone components into the housings and inserts and placing them into a shipping case. Before placing the product into the shipper, an operator applies a pressure-sensitive label to the housing. The thermal-transfer-printed label includes a bar code that contains product information and serial number. That information is then scanned, and the data is transferred to a thermal-transfer printer. This printer applies the scanned information onto another p-s label that's hand-applied to the shipping case downstream. Merriman describes the equipment as standard and not new or unique to this project.

The elimination of the shipping case and the plastic bag has cut down time in assembly. "It's a step less in our manufacturing process, and there is a reduction in labor costs," says Merriman, "but we don't have a good way to quantify it. We also have the ability to produce more product. Before, we may have taken 60 to 65 seconds to pack one box; now it takes 45 to 50 seconds. We build to stock products so that we have about a week or two of inventory, and we ship globally from our plant."

Merriman says there are three manual packing stations at the end of the assembly area that use the molded pulp inserts. One operator at each station packs products. It's a two-shift operation, five days per week. The inserts are used for three Definity® products: a Callmaster® voice terminal, an Attendant Console and a DXS Console. These phone systems weigh between 4 and 6 lb and measure 8" to 10"Wx6" or 7"H.

Finding an alternative

Although personnel at Lucent's Denver plant first started using the molded pulp cushions last December, they "began checking with vendors about three years ago to see if there was something else out there that might work better than the EPS and could provide a cost savings for us," says Merriman.

At the same time, the aluminum tooling that Lucent's fabricator had used to mold the EPS cushions was wearing down. "We owned the tooling, which typically has a life cycle of about five years. Ours was seven years old, so it was at the end of its life."

In the search for an alternative, Merriman says Lucent "looked at molded pulp, but most of it was used for heavy corner caps for furniture, not for smaller products," like the phone terminals shipped from the Denver plant. "We contacted three or four [molded pulp] companies," he says. "The only company that was interested in pursuing our project was Eco-form."

Custom molding

Eco-form used actual Lucent products to develop the custom top and bottom inserts that could be used by Lucent's molder to pack the outer product housings, then through Lucent's assembly and distribution phases.

Eco-form made the aluminum tooling for both inserts. To manufacture the inserts, the tooling is placed on a platen. The platen rotates the tooling into a 120°F slurry for three or four seconds. The slurry contains 97% newspaper, as well as small quantities of corrugated, a wax emulsion to reduce dusting and provide moisture/water resistance and liquid resin sizing that adds strength.

The mix is drawn onto a metal mesh screen around the mold. Vacuum holes in the mold are used to draw the fiber and water slurry to the screen. Vacuum is used to draw out water after tooling rotates out of the slurry. Once out of the slurry, a transfer die moves over the screen, using vacuum pickers to remove the product. The transfer die holds the molded material briefly before releasing the insert onto a conveyor that carries it through a 400°F dryer.

The dryer removes about 90% of the moisture from the insert. The part cures completely in seven to 10 days, according to Jalal Khan, plant manager at Eco-form's Walpole, MA, plant where the inserts are manufactured on a T1002 machine from Emery Intl. (Markham, Ontario, Canada). Purchased in 1997, the machine produces Lucent's inserts at a rate of 12/min. Khan says three dies are used per platen and one complete cycle takes 15 seconds. Finished inserts, in 4- to 5-mm thicknesses, are shipped to Hisco for just-in-time delivery to Complex Tooling.

Change pays off

"The molded pulp is designed to follow the contour of the product," says Merriman. "The inserts encapsulate the whole finished goods product in the case, so they provide better protection than the two EPS cushions we had used, which were just placed at the ends of the product. The new packaging meets or exceeds the requirements of final product packaging according to compression testing by our vendor and our own internal testing. The inserts are also safe from ESD. They meet our requirement of no more than 100 volts of charge build-up for items shipped to the factory floor. They're also static- and dust-free. The EPS cushions were somewhat abrasive."

All of these advantages helped the Denver plant justify the switch to the molded pulp inserts, which, Merriman says, "are about 10- to 15-percent more expensive on a piece-cost basis." But factor in the reduced assembly labor and elimination of the ESD bag, and "it's about a break-even. The economics of the decision are not an overriding factor," he says.

The two inserts earned Lucent an Ameristar award from the Institute of Packaging Professionals (Herndon, VA) for molded pulp in 1998, and an Ameristar Silver Star in the competition's electronics packaging category.