From its earliest days, music and video distributor Valley Media, Woodland, CA, has attempted to ship every order to its independent and chain store customers the same day that it's received. Today, with over 200ꯠ pieces being shipped daily from its warehouse outside Sacramento, Valley Media relies on two labeling/sortation/collating lines supplied by Dorner Manufacturing Corp. (Harland, WI). The more recent of the two started up about a year ago, and is controlled by 126 micro PLCs from Siemens (Alpharetta, GA). (The old line is controlled by one central controller.)

The micro PLCs have contributed to a reduction in downtime by more than half, from about 5% on the old line down to 2% on the new line. To understand the benefits this distributed control brings to Valley, here's an explanation of what the lines do and how they operate.

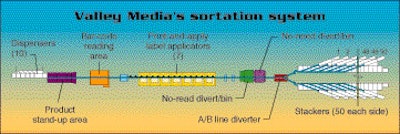

First, workers pick individual tapes, CDs and videos from inventory in batches of 100 orders. The picked merchandise is hand-loaded into 10 infeed magazines or dispensers at the beginning of a line. Pieces are conveyed single-file past a pair of bar-code scanners that scan the manufacturer's preprinted UPC codes on the side of each primary package. At that moment, the system decides which customer will receive that piece, and tracks the movement of that piece as it travels throughout the remainder of the line.

After scanning, the products are conveyed past a bank of seven Label-Aire (Fullerton, CA) printer/applicators. Each piece receives a custom price label (if desired by the customer) that may include a retailer-specific bar code, price, media title and other information. Labels may vary from one piece to the next, even for the same SKU, since they may be "assigned" in the system's memory to different orders.

After labeling, each piece is sorted via conveyors and diverters to one of 100 stacking stations. Each stacker represents a specific order. Once the piece arrives at a stacker, it is stacked against the piece that preceded it until a group of 15 pieces are accumulated. Stacked batches emerge sideways on roller conveyors at each stacker like loaves of bread. When the stacker's light beacon signals an order is complete, an operator grabs the stacks and loads them into a pre-erected corrugated shipper. Boxes are then conveyed downstream for sealing and labeling.

About seven people work on each line, both of which operate at 200 pieces/min.

Benefits of distributed control

The 50%-plus decrease in downtime can be traced to three benefits of distributed control. The first is that if any one part of the line, say a stacker, goes down for maintenance or repair, the rest of the line can continue to operate. That's because each stacker has its own safety switch and its own PLC that shuts it down in the event of a jam. Other stackers and the rest of the line continue running.

"I can't stress how big a benefit that is," says John Kordic, senior vice president of operations.

That's not the case on the original line, where a jam at any one machine would trip a single light curtain running the length of the line, causing the controller to shut down the entire line. "On the old line, you couldn't even touch any of the stackers unless you turned off the light curtain," says Ken Adams, facilities manager.

A second benefit of distributed control is that the 126 micro PLCs not only control the line, they also monitor performance, alerting operators of potential problems before serious trouble occurs.

Kordic explains: "Metal pieces and bushings eventually wear out. When that wear is severe, what used to take one hundredth of a second now takes two hundredths of a second." Since time represents product movement, any such delay in, for example, a diverter arm, could conceivably affect whether a piece is actually physically transferred from the conveyor to the stacker.

If a piece doesn't arrive at its intended stacker, it's ejected from the end of the line and isn't included in the order. "Because we only invoice what we ship, that means we've lost a sale," says Kordic.

The new line reduces this so-called runoff by at least a third compared to the old line, says Adams. The reason: Because control of the line is spread out among 126 controllers, each controller has a much simpler program. That means there's room for extra programming that permits each PLC to monitor its little section of the line for trouble. A micro PLC on a stacker not only triggers a pusher arm to push a CD into a stacker, it can measure how long it takes, notifying operators of any anomalies via a screen on the central PC that runs software that coordinates the actions of the individual PLCs (see sidebar, p. 149).

"The software [running on the PC] allows us to recognize where we're possibly losing product or see if we're having problems with certain stackers," confirms Adams.

Another benefit of distributed control is that troubleshooting is faster. That's partially because potential errors are reported early, as described above. But it's also because Valley personnel can tap into each micro PLC with a Dorner-supplied, portable, touch-screen display to facilitate troubleshooting.

For example, in diagnosing a stacker problem, Valley workers can view the timing for each sensor, actuator and other device on the stacker while it's running. By comparing the data with how long various functions should take, Valley can diagnose a prob-lem. Maintenance personnel can also jog the stacker through its various move-ments, again monitoring timing at each step of the way.

"It's very helpful, and we use it all the time," says Adams. "It cuts down on troubleshooting time by at least fifty percent," he says, which accounts for a substantial part of the 50%-plus downtime reduction.

Easier to build

Although the new line required an investment in 126 micro PLCs at a cost of about $400 a piece, that expenditure was more than offset by the savings in engineering time required to program the PLCs and less time needed to manufacture and install the line.

According to Dorner, the time for writing (and replicating) a simple program for 126 micro PLCs is significantly less than that required to write a huge, complex program for one central controller.

Also, time is saved in the manufacture, assembly and installation of the various machines that make up the line. That's because the thousands of sensors, pushers, lights and other devices on the line only need to be wired to each machine's PLC, instead of to a central control panel. Not only is such wiring expensive and time-consuming, it also couldn't be done until the line was assembled on Valley's floor.

With the new line, much of the device wiring to individual PLCs was done at Dorner's factory, greatly reducing the time required to install the system in the field. And shorter wire runs are needed.

As a result, the new line cost about the same as the old one, confirms Kordic, even though it was built three years later and provides a higher throughput. And though the higher throughput comes from re-engineered stackers rather than controls, Valley still received a "next generation" line, says Kordic, at the same cost as the old one, thanks to the cost reduction in controls engineering.

High accuracy

For Kordic, the control system, along with the equipment itself, results in a labeling, sorting and collating system that fulfills orders accurately. Recent shipping accuracy measurements from Valley's customer service department, based on customer complaints, have come in at 99.96% to 99.97%. "Our customer service has to take it to the hundredth of a percent to reflect any movement on it," says Kordic. "We're almost perfect. It's truly amazing."

In fact, Valley's accuracy is so high that several of its bigger customers have taken to scanning a single bar code on the outside of a box for receiving, in lieu of scanning each individual piece. That bar code permits their computer system to download the data for each individual piece from Valley's computer system.

Such a practice is referred to as ASN, or advanced shipping notice, and is a UCC standard that allows the transfer of data to take place smoothly and accurately. Valley has been offering this service to its customers for more than a year.

So customers must have great faith in the accuracy of Valley's distribution system, right?

Kordic laughs. "Not only do they have great faith, they also issue great penalties if they catch us doing it wrong. So we have to have great faith that we're not going to make a mistake."

Although not all of Valley's customers are sophisticated enough to take advantage of ASNs, Kordic says Valley wouldn't hesitate to do all of its business that way. "Not all of our competitors can offer ASNs," he says. "That gives us a competitive advantage."