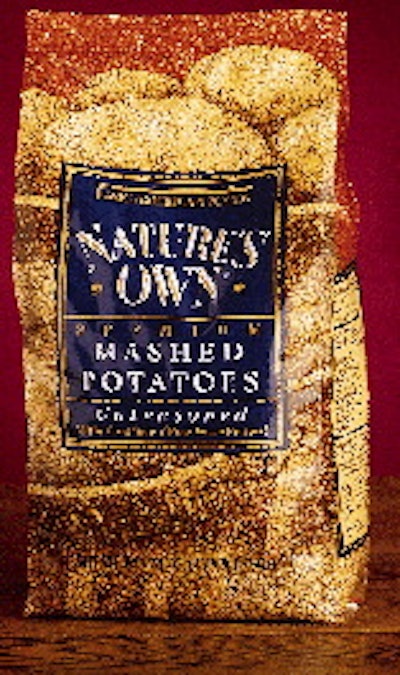

Bags of Nature's Own(TM) dehydrated potatoes may not rival the masterpieces of artist Georges Seurat. But the bag graphics do echo Seurat's pointillistic methods, the end result being a package that would stand out on any store shelf. That's why it's surprising to learn that these potatoes, marketed by Basic AmericanFoods of Walnut Creek, CA, are exclusively sold to foodservice accounts.

To be certain, the points of color that adorn the bag's background of whole russet potatoes are eye-catching. More distinctive, though, are the stand-up bag's four "pleated" edges that many may recognize as the Stabilo Bag(TM) made on a machine from Rovema (Lawrenceville, GA). Rovema confirms that Walnut Creek, CA-based Basic American Foods is the first U.S. user of the Stabilo bag for foodservice. Nestlé Chocolate & Confections was first in the U.S. to use the bag for a retail product last August, with its introduction of Pretzel Flipz(TM) (see Packaging World, Sept. '97, p. 2).

The 1.75-lb foodservice bags are made on Rovema's continuous-motion Model VPR-320 vertical bagger, at Basic's Blackfoot, ID, facility. The machine was added last summer to launch the Nature's Own seasoned and unseasoned dehydrated mashed potatoes.

Other products are also under consideration for packaging in the Stabilo bag, according to the company. Basic American Foods dehydrates vegetables, mainly potatoes and beans, for foodservice customers. Basic also supplies the products in bulk to processors as ingredients.

"This is a new brand and [to introduce it] we chose the Stabilo bag. It has a distinctive appearance, with four sealed vertical edges and a gable-like top," notes Larry Parks, section leader in packaging engineering at the Blackfoot plant. "First, we feel it's a functional and attractive bag. In our [foodservice and institutional] markets, that's very important," he points out. "We've done considerable customer testing, and we've learned that they really want an all-around quality package. Like a consumer at a grocery store, if a customer, say a chef, sees this bag, its form and graphics will communicate that there's a quality product inside."

The focus on this package stems from Basic's top management, which views graphics as more than merely cosmetic. "There is a growing need to provide [customers], food preparers and waitstaff with more information," says Gordon Lewis, vp of new business development. "One means to do this is to use packaging graphics to better differentiate product quality and usage applications."

Designed along with SBG Partners (San Francisco, CA), the bags for delicately seasoned and unseasoned potatoes are nearly the same, with the exception of certain graphic elements. The unseasoned version features blue-colored rectangular blocks for front, back and side panel copy while green is used for the seasoned variety. Detailed preparation instructions for hand or machine mixing, as well as recipe suggestions, are printed on a large back panel.

Basic American Foods selected the Stabilo bag for more than artistic merit, however. "The package was designed to be easy to handle, stack well, provide strong product identity and minimize packaging waste," says Lewis.

Parks says that the Stabilo bag "uses about ten percent more material than a standard flat-bottom stand-up bag." However, he believes it is worth the extra cost "because of its design and strength advantages, and the results we think it will give us in the market." He says that Basic's handling, compression and transportation testing proved that the unusual edges give the bag "quite a bit of additional strength compared with other flat-bottom stand-up bags.