Early last year, a Packworld.com survey solicited its audience on packaging lessons learned. More than 150 respondents took the time to craft stories of their experience (see www.packworld.com/view-21145). We had thought that response was pretty good.

We went back to the well this year, again asking about packaging experience, and to relate any “eureka” moments where ingenuity or resourcefulness may have kept a project on track and saved the day. This year’s response, with 444 survey takers, should be considered truly amazing. Respondents included vendors, contract packagers, consumer packaged goods companies, and others. Some of the more than 100 CPG employees who participated included representatives from General Mills, J.M. Smucker, M&M Mars, Nestle, Schering Plough, and others.

What you shared this time ranged from the obvious and general to the illuminating and specific, and much more than could be used in this report. We hope, this collection of observations and insights, edited for clarity, will make all of us wiser and perhaps save you and your company some frustration, effort, and money on your next project.

Communications counsel

The responses were all over the board, though a number have learned and recognized the importance of communications, in its various forms, as a crucial ingredient for success.

“The best way to ensure success is to have a clear and constant communications with all team members at all levels of the organizations as the project progresses—and even more as it runs into unpredicted issues or outcomes,” wrote one respondent.

Wrote another: “Personnel [should] develop an intimate understanding of the packaging equipment, and the interactions of product and people, noting the limitations of each and opportunities for improvement.”

Another admonished managers to “get out from behind your desk and your e-mail. Go onto the manufacturing floor and talk with production personnel. Production personnel are a wonderful asset, so be sure to include them in your projects.” Another echoed the same thought: “The best way to understand something is to get out on the frontlines and witness it firsthand.”

Wrote another: “Lots of little ‘discoveries’ usually come from asking questions and truly listening to answers.”

Several have discovered the benefits of brainstorming, including this manager: “Several times someone in a brainstorm session suggested a solution so simple that we all wondered why no one had thought of it before.”

There are those who have learned that project success can result as much from arranging who should be at a meeting—and who shouldn’t. “Many years ago we had a project to pack cheese into a tub with a gas-flush. The residual air had to be under 1%. Getting close to that was easy, but the last little bit was tough. Finally, we sent the boss and the customer on a long lunch so we could concentrate on work. Once it was quiet, we could think, and by the time they came back from lunch, were at 0.7%.”

A number keyed in on product variability, which should be taken into account even during package development. Wrote one manager, “You need to know the product going into the packaging and its requirements before designing the package.”

Echoed another respondent, “every product is different and variable. If you don’t know and can’t control the variability in your product, you won’t successfully package it.”

Write a third, “every item is different, and the more different they are, the harder it is to efficiently pack them.”

Package design advice was also shared. Several of these respondents such as this one noted the importance of package mockups: “Always make a mockup of your packaging. You may think you have all the graphics in the right place until your supply arrives. It doesn’t hurt to make a ‘mini’ so that you can see where you are headed.”

Wrote another, “A picture is worth a thousand words, so mockups will save you time and money.”

Plant floor machinery problems were also addressed—as were assumptions.

“If a machine that has just had work performed by the maintenance department is not working correctly, check for setting errors,” wrote this supervisor. “Don’t accept assurances that it has been done according to the manual.”

The related topic of center-lining equipment was chronicled several times. One manager noted a problem with a cartoner that would not consistently pick properly, and kept dropping the cartons. “The hopper was not center aligned. It was a simple fix that took six hours to find. Duh.”

Another also pointed to attention to detail in center-lining and aligning rails and guides: “Take the time to correctly set up and you’ll have a far smoother run.”

Others offered precise guidance based on their own specific experiences, such as this manager: “Product was breaking through the bottom of the bags, so we added baffles to the inside of the vertical form/fill/seal tube to reduce the products’ velocity.”

Cost-saving advice

Cost-savings was another focal point for learnings. Here are some examples:

“Creating packaging out of the gate that’s tri- or bilingual will save in printing costs and inventory.”

“I have proven numerous times that sometimes by increasing the cost of packaging, it will show cost-savings or more profits in the long run through less damage or returns, fewer freight claims, longer shelf life, and greater shelf appeal.”

“We experienced a cost-saving project on an HDPE bottle by changing the polymer grade.”

“We reduced the structure from 1.25 mil to 70 ga, which resulted in a net savings of $1.5 million per year.”

“A switch from a 38-mm closure to a 28-mm closure finish saved more than $350 million.”

It doesn’t take saving millions of dollars to be a victory, as this testimonial illustrates: “For one of our products, a lip balm in a tube, I ordered more tubes from an online supplier and found a tray that loads the tubes for filling and helps reduce product loss. This small piece of ‘equipment’ cost about $10, but saves us a lot of time and money by reducing waste.”

Then there was advice that is just good advice no matter what the savings happen to be:

• Slow the line to the design speed. Our result? Efficiencies went sky high!

• I have learned that once we have good product, even small changes could mean big problems, so we need to be very careful with the design and its specifications. An example is that if you switch one approved raw material for another approved raw material, you may face problems.

• Never assume anything, and take the time to test when possible. The best shipping trial advice is to over-package to start; you can always reduce the materials later.

• Equipment may only produce X number of packs per minute, but how they present those products to downstream equipment can have a huge impact on productivity.

The lighter side

I personally got a kick out of some of the responses, and I’m guessing you will, too:

• We have probably had many eureka moments over the years, but I cannot identify one.

• I subscribe to the work principles to “keep it simple stupid” and “less is more,” learned from others not using these two principles!

• Marketing will change the package until you tell them they no longer can (known as MISS—Marketing-Induced Stress Syndrome).

• Not everyone holds the correct title—most work below their credentials. I know this sounds negative, but the reality is that keeping this in the back of my mind helps me understand why people act as they do.

• High quality, low price, and fast turnaround never meet. You can pick any two of these but if you try to obtain all three, you will fail.

• I learned that there are many ways to solve a problem, but only one best way. The trick is that you never know if you’re using the best solution, so keep looking.

Here is one that as an editor I greatly appreciate: There is no such thing as proofreading too many times.

It is often possible to determine who among our survey takers are optimists and who are pessimists. What would you make of this one: “Eureka moments are rare and in fact may be an illusion. Most eureka moments come as a result of fatigue after a lot of hard work.”

Sometimes separate survey responses work in tandem very well, like these examples:

1. Think of cutting labor by getting a simpler-to-pack packaging that might cost a little more money, but saves labor in the long run.

2. Labor is the key component in any packaging line.

You must also adapt any advice to your particular situation because what works for one may not work for another. One person noted that his company improved its production by rearranging the machines from a straight-line layout to a U-shaped layout. Contrast that reply with this reply: “I experienced a eureka moment when we decided to put all of our packers on an I-shaped line instead of U-shaped line.”

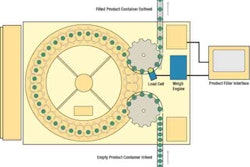

Some painted a picture with words, as this example shows: “A packaging line flows like a garden hose; if you constrict the flow of product, the pressure upstream begins to build and the downstream is starved. Due to this effect, accumulation is very important to keep flow going.”

Then there are these nuggets:

• A package redesign takes longer than your management will be willing to schedule for you.

• One important lesson I have learned is to make sure you have the correct size of the contents before making the package.

• A well-structured company will prevent everyone from reinventing the wheel over and over again.

Then there were those who emphasized their point with exclamation points (!):

• Be careful!

• Never give in!

• Assume nothing, check once, twice, thrice!

• Do not transport air!!

• Test, test, and retest!

• Automate!!!!!

One reminded us that experience is the best teacher, bar none: “There is nothing that replaces on-the-job experience. No college education, no tradeshow seminars, no trade magazines or the like. Experience, experience, experience.”

In conclusion, this respondent may have captured it best: “The need for innovation never stops. The packaging for many different products is called upon to do more beyond protecting the product on its way to market. Such as keeping children out, and making it easier for seniors to get in; ensuring the product inside is authentic by making it unprofitable or impossible for counterfeiters to replicate; selling the product by attracting the buyer; serving as a cooking vessel; serving as a handy dispenser; protecting against exposure; and for doing all these essential jobs at a reasonable cost—and with minimal impact on the environment.”

Whew, that’s asking a lot from packaging, vendors, and packagers. It is also why we will all continue to adapt, and to learn from our successes, our failures, and from each other.