This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

New washdown-capable IP69K and track-changing versions of the eXtended Transport System (XTS), along with updates to the fully integrated portfolio of Industrial PC (IPC), EtherCAT I/O, drive technology, mechatronics and TwinCAT 3 automation software technologies, are just a few innovations that will be on display

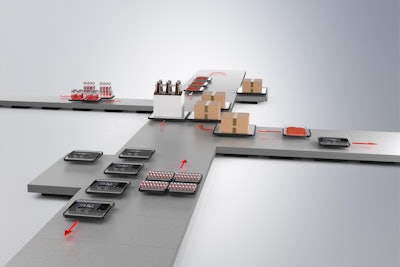

The eXtended Planar Motor system, XPlanar, offers unparalleled capabilities for adaptive packaging, material handling and inspection, along with opportunities to shatter conventional thinking in automation, implement non-linear processes and enable true lot-size-1 production. The Flying Motion system from Beckhoff creates no contamination through contract-free and wear-free movement, and the freedom to use any surface covering – stainless steel, glass, plastic, etc. – makes XPlanar a sanitary, washdown-capable solution. This will be the technology’s in-person debut at a PACK EXPO event.

PACK EXPO attendees can also expect to see the latest updates to the intelligent XTS from Beckhoff. This linear transport system – which has already delivered high speeds, machine footprint reductions, instant changeovers and real-time integration with robotics and other systems – also offers a stainless-steel version and track-changing capabilities. The IP69K XTS Hygienic perfectly suits washdown production environments in packaging, pharma, food, beverage and more. XTS Track Management further boosts the system’s flexibility with the software and hardware functionality to transfer movers between multiple XTS tracks, which enhances customization, quality inspection, automatic defect ejection and other critical production and packaging tasks.

PACK EXPO Las Vegas and Healthcare Packaging EXPO (Sept. 27-29, Las Vegas Convention Center) will reunite the packaging and processing community. With over 1400 exhibitors, no other event in 2021 will bring together a more comprehensive gathering of suppliers offering new products, technologies and solutions. Attendee registration is now open.

Beckhoff will showcase new technologies from every product family, including TwinCAT 3 software, which offers a comprehensive engineering and runtime environment, along with integrated packages for IoT, analytics, robotics, machine vision and machine learning. Power measurement, overcurrent protection and TwinSAFE functional safety are just a few of the EtherCAT I/O solutions that will be on display. The C60xx ultra-compact IPC series will return to PACK EXPO with new variants to suit even more applications, and attendees will get a comprehensive look at the full IPC portfolio through many other introductions in the Beckhoff Embedded PC, Panel PC and Control Panel lines.

As top drive technologies for world-class packaging machinery, the AX8000 multi-axis servo drives and AMP8000 distributed servo drive system will be on display in the Beckhoff booth. Control cabinets are increasingly eliminated from machine design with Beckhoff’s distributed, machine mountable products that include industrial PCs, I/O, drives and motors. Visitors will also see a complete compact motion solution that includes DIN-rail- and machine-mountable I/Os for servomotor, stepper, DC, and BLDC motors as well as PWM output terminals, all of which save valuable footprint in packaging operations.

“This year’s live PACK EXPO Las Vegas presents many unique opportunities to explore the latest innovations in packaging automation and mechatronics – and to see how the technology landscape changed since we were last able to gather in 2019,” said Mark Ruberg, Packaging Industry Manager for Beckhoff Automation LLC. “While in-person events were on pause, Beckhoff did not take a break in releasing groundbreaking new automation technologies. Powerful updates to our XTS, EtherCAT, IPC and TwinCAT products, not to mention showing XPlanar in person, are certain to spark many conversations and lead to exciting new packaging machine concepts that can propel the entire industry forward.”