At its Cayey, Puerto Rico, facility, Alcan Packaging manufactures plastic containers for pharmaceutical and cosmetics applications. Alcan Packaging, formerly known as Wheaton Plastics, dedicates some of its molding equipment at Cayey to the production of jars and lids sold to Procter & Gamble for Noxzema and Oil of Olay skin-care products.

Recently Alcan invested in a system designed and custom-built for them by supplier Schneider Packaging Equipment. The system smoothly conveys the containers from molding machines to a robotic cell area where a Motoman robot automatically palletizes them. Pallets are then conveyed onto a Schneider shuttle car that delivers pallets downstream to a new stretch wrapper from ITW Muller.

The Schneider-integrated system, which began running early last year, has reduced the need for eight workers at the plant, which was part of its economic justification.

Both Alcan Packaging and P&G wanted to upgrade the palletizing process at Cayey. That process formerly involved two large palletizers. Although they automated palletizing, they were considered too labor-intensive, says Noé González, the plant’s technical support manager.

“The two palletizers pushed the jars over a pallet, one layer at a time,” he says. “When the layer was on the pallet, it was lowered, a worker put a slip sheet on top, and the next layer would be swept onto the slip sheet, and this would continue until the pallet was completed,” recalls González. “This required an operator at all times. Slip sheets had to be manually placed on every layer, and a significant number of the jars, especially the lighter-weight ones, fell due to erroneous movement of the system.”

Alcan runs the palletizing system on two daily 12-hour shifts, seven days a week. It accommodates output from four upstream molding machines. Two injection blow-molders produce 2.5-, 6-, 10.75-, and 14-oz high-density polyethylene jars for Noxzema, in blue or white. Two of the machines injection-mold polypropylene jars for Oil of Olay products made in natural or gray colors, in 50-, 60-, and 100-mL sizes.

In June, the Schneider system began accepting output from a fifth line that supplies strapped plastic trays of injection-molded PP Oil of Olay lids (Noxzema lids are not part of this project).

Seeking a solution

Before purchasing an automated robotic system, Alcan contacted three primary vendors to bid on the project. “Most vendors told us ‘these are the models we offer,’” says González. It wasn’t until after visiting Schneider that he, along with Cayey plant general manager Rafael Benitez and engineers Glenn Estad and Dan Lock, made the decision to buy the system.

González says he found out about Schneider through Motoman. “I had worked with a Motoman robot in my last job for seven years,” he says. “The experience was incredible.”

According to González, P&G didn’t specify the equipment. “We just let them know what we were doing,” he notes. “We have a contract with them, and we own the equipment.”

The overall process for palletizing jars from the four molding machines is similar, though there are differences in the way in which jars are conveyed from the molding equipment.

“When Oil of Olay jars discharge from their two machines, they go onto an elevated conveyor,” explains González. For both of these molding machines, jars discharge onto an approximately 10’-long flat tabletop chain conveyor section. When the group of jars (the molders produce as many as 16 at a time) convey onto this section, the conveyor is shut off.

A servo-driven system with bearings then elevates this section of conveyor up to a 7’ height, the conveyor is turned back on, and the jars convey along an overhead conveyor mounted to both the wall and the floor. Once those jars are released, the conveyor descends back into its home position. According to Schneider, this happens about every 30 seconds. Elevated conveyors are necessary because of space limitations at the plant.

Jars convey through a cooling tunnel for 30 seconds for curing. This is especially important for thick-walled containers that cannot be touched until they cure. From the cooling tunnel, the jars are conveyed to the robotic palletizing cell.

Noxzema jars are handled a little differently. When they exit the molding machines, they’re on conveyors about 3’ above floor level. They move to an overhead height slightly lower than the Oil of Olay jars. But they do so by way of an S-shaped conveyor towards the robotic cell, rather than the elevator device used for Oil of Olay.

On to palletizing

Four lines of jars convey single file from the cooling tunnel in the molding area through a wall into a warehouse that contains the fully enclosed robotic palletizing cell. Fenced in for safety, this area measures approximately 30’x70’.

The palletizing system is programmed to allow Alcan operators to switch back and forth between the various jar sizes and trayed lids. This is done through an Allen-Bradley Control Logix PLC control system with operator interface; it was supplied by Rockwell Automation.

Jars accumulate in their four conveyor lanes until the correct number is reached for one row of one pallet layer. This number varies depending on the jar type and size. Jars are placed in a staggered arrangement on each layer so that one row might have 16 jars, the next row 15, the next 16, and so on. That helps stabilize jars on each layer.

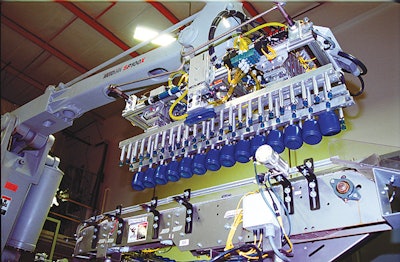

To lift the jars, the Motoman robot selects one of six end-of-arm tool heads. Each head accommodates a different-diameter jar. The control system tells the robot to drop down the appropriate tool head and pick up as many as 16 jars from the conveyor with its vacuum cups.

The robotic arm moves in an arc, picking up jars from conveyor one and placing them onto pallet one. Jars from conveyor two are placed onto pallet two, and so on.

Oil of Olay lids in their 360-count plastic trays are conveyed from the new fifth line into the robotic cell. This line is positioned in the very center of the four jar lines.

The robotic arm also picks and places wooden pallets and slip sheets as necessary. The slip sheet dispenser station is located next to the two Oil of Olay jar lines, while the pallet dispenser station is positioned by the two Noxzema jar lines.

Once a full pallet load is completed, it’s discharged onto a drag-chain pallet conveyor. The Schneider shuttle car moves along a path perpendicular to the four pallet discharge conveyors. The shuttle car rides on polyurethane wheels that travel along a track bolted to the floor. The car rolls to the appropriate pallet location to accept the filled pallet. Once the pallet conveys onto the shuttle car, it is delivered to the ITW Muller Octopus stretch wrapper.

“The wrapper rotates around a stationary load,” says González. “The machine works really well,” and was priced right compared to other wrapper machines the company considered, he says. Stretch-wrapped loads are then driven by forklift to a designated area in the warehouse.

Since the system’s been running, says González, “we’ve not had a need for any service. I’ve been impressed with the Schneider equipment from the beginning. We rely on it every day.”

Not only has the robotic system saved in labor costs and eliminated the costs associated with jars falling during the previous palletizing process, it’s also saved valuable floor space at the plant. “The robotic area takes up the same floor space as the other two big palletizers we used to use,” says González. He also notes the robotic equipment is flexible enough to be used for different applications, though it’s dedicated to the P&G jars and lids. González estimates the return on investment for the system is “a little more than two years.”